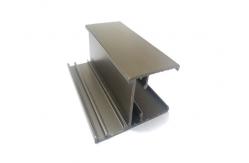

6063-T5 Sand Powder Coated Aluminum Extrusions Broken Bridge Aluminium Section

|

6063-t5 Aluminum Window and Door Profile Sand Powder Coated Aluminum Extrusions Broken Bridge Aluminium SectionProduct Details:

Introduction:Powder spraying is to spray powder coating on the surface of workpiece through powder spraying equipment (electrostatic spray molding machine). Under the action of static electricity, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating; the final coating powder spraying effect with different effects (different powder coating effects) is superior to the mechanical strength, adhesion, corrosion resistance and aging resistance of the spraying process, which is also affected by the cost of spraying.

The coating is mixed with special resin, pigment, filler, curing agent and other auxiliaries in a certain proportion, and is made by hot extrusion, crushing and screening. It can be stored stably under normal temperature. It can be made into smooth and bright permanent coating by electrostatic spraying, friction spraying (thermosetting) or fluid bed soaking (thermoplastic), and then heating and curing, so as to achieve the purpose of decoration and corrosion prevention.

Advantages:

1.High Efficiency: Because It Is Disposable Membrane, It Can Increase Productivity 30-40% 2.Save Energy: Reduce Energy Consumption By About 30%. 3.Less Pollution: No Organic Solvent Volatilization (Not Containing Toluene, Xylene And Other Harmful Gases In Paint). 4. The Coating Utilization Rate Is High: Up To 95%, And The Powder Can Be Used Repeatedly After Recovery. 5. Film Performance Is Good: Disposable Film Thickness Can Reach 50-80 M, Its Adhesion, Corrosion Resistance And Other Comprehensive Indicators Are Better Than The Paint Process. 6. Finished Product Rate Is High: Before Curing, It Can Carry Out Two Times Re Injection. There Are Many Kinds Of Powder Coating Process, And There Are Two Kinds Of Electrostatic Powder Spraying And Plastic Dipping. Powder Coating Is A New Type Of Solid Powder Coating Without Solvent 100%. It Has The Characteristics Of No Solvent, No Pollution, Energy And Resources Saving, Labor Intensity Reduction And Mechanical Strength Of Coating Film.

Photos:

Please tell us the information below, and we will give the best suggestion to you !1. Where you intend to use the aluminium profiles? 2. If you have the estrusion drawing, send us and we develop the correspondence mold. 3. Which color you want or tell us the architectural style you like. 4. Purchase quantity. It will convenient us to give you the best price. |

||||||||||||||||||||||||||||||||||

| Product Tags: standard aluminium extrusions powder coated aluminum profile |

|

White Color Aluminium Extruded Profiles For Kitchen Cabinet Door U Corner |

|

T8 Powder Coated Aluminium Extrusions 6.0m Length For Window Groove Pressing Line |

|

Non - Toxic Fire Powder Coated Aluminium Extrusions 6063 T5 Deep Beige |

|

Green Powder Coated Aluminium Extrusions For School Windows Frame |

|

0.8mm Thickness Powder Coated Aluminium Extrusions For Windows And Doors Customized |

|

6m Length Powder Coated Aluminium Extrusions Aluminum Window Frame |