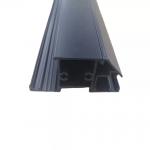

6063 T5 Extrusion Aluminum Profile For Muaritius Sliding Windows

Extrusion:

Extrusion is a means of profile forming. First, according to the

section of the profile product, the mold is designed and

manufactured, and the heated round casting bar is extruded from the

mold by the extruder. For 6063 alloy, an air cooling quenching

process and an artificial aging process are used to complete the

heat treatment. Different brands of heat treatable strengthening

alloys have different heat treatment systems.

Coloring (here we mainly talk about the process of oxidation)

Oxidation: the surface corrosion resistance of extruded aluminum

alloy profile is not strong, so anodizing is necessary to improve

the corrosion resistance, wear resistance and appearance of

aluminum profile.

The main process is as follows

(1) Surface pretreatment: chemical or physical methods are used to

clean the profile surface to expose the pure substrate, so as to

obtain a complete and dense artificial oxide film. It is also

possible to obtain specular or matte (Matt) surfaces by mechanical

means.

(2) Anodizing: after surface pretreatment, under certain process

conditions, the substrate surface is anodized to form a dense,

porous and strong adsorptive alumina film.

(3) Sealing: the pores of the porous oxide film formed after

anodization are sealed to enhance the anti pollution,

anti-corrosion and wear resistance of the oxide film. The oxide

film is colorless and transparent. By making use of the strong

adsorption of the oxide film before sealing, some metal salts are

adsorbed and deposited in the film hole, which can make the profile

appearance show many colors other than its original color (silver

white), such as black, bronze, gold and stainless steel.

Profile Specification:

| Description | 6063 T5 Extrusion Aluminum Profile For Muaritius Sliding Windows |

| Material Thickness(t) | 0.8-2.0 mm |

| Materiral | aluminum alloy 6063 |

| Annealing Treatment | T3-T8 |

| Color | Wood, Silver White ,Bronze , Champagne, Black, (RAL series)etc. |

| Surface Treatment | anodized, powder coated, electrophoresis, wood grain, polished and

etc |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation,

Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile;

2. Wrap with shrink film exterior;

3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical

performances to adapt all kinds of architectural styles |

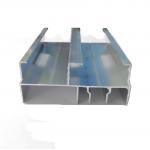

Aluminum Windows Doors:

Thickness

There are 70 series and 90 series of aluminum alloy sliding doors,

and 70 series can be used for aluminum alloy sliding doors in

residential buildings. Series number refers to the millimeter

number of the structural dimension of the door frame thickness.

There are four kinds of aluminum alloy sliding windows: 55 series,

60 series, 70 series and 90 series. Series selection should be

based on the size of the window opening and the local wind pressure

value. Aluminum alloy sliding window used as closed balcony shall

not be less than 70 series.

Strength

The tensile strength should be 157 n / mm 2 and the yield strength

108 n / mm 2. When purchasing, the profile can be bent moderately

by hand, and it should be restored to its original state after

releasing.

Chroma

The color of the same aluminum alloy profile should be consistent.

If the color difference is obvious, it is not suitable to purchase.

Planeness

Check the surface of aluminum alloy profile, there should be no

depression or bulge.

Gloss

Aluminum alloy doors and windows to avoid the purchase of open

surface bubbles (white spots) and ash (black spots), as well as

cracks, burrs, peeling and other obvious defects of the profile.

Oxidation Degree

The thickness of oxide film should be 10 microns. When purchasing,

you can draw on the profile surface to see whether the oxide film

on the surface can be wiped off.

Specifications

1 the opening size of doors and windows shall comply with the

provisions of GB / T 5824 "series of opening size of doors and

windows in buildings".

2 dimensions and specifications of common window openings

one thousand and two hundred × 1500mm

one thousand and five hundred × 1500mm

one thousand and eight hundred × 1500mm

Aluminum Profiles Features:

Corrosion Resistance

The density of aluminum profile is only 2.7g/cm3, which is about

1/3 of that of steel, copper or brass (7.83g/ cm3, 8.93g/ cm3,

respectively). In most environmental conditions, including in air,

water (or salt water), petrochemistry and many chemical systems,

aluminum can show excellent corrosion resistance.

Conductivity

Aluminum profile is often selected for its excellent conductivity.

On the basis of equal weight, the conductivity of aluminum is

nearly 1/2 of copper.

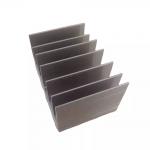

Thermal Conductivity

The thermal conductivity of aluminum alloy is about 50-60% of

copper, which is beneficial to the manufacture of heat exchanger,

evaporator, heating appliance, cooking utensil, cylinder head and

radiator of automobile.

Nonferromagnetism

Aluminum profile is non ferromagnetic, which is an important

feature for the electrical and electronic industries. Aluminum

profiles cannot be self ignition, which is important for the

application of handling or contacting inflammable and explosive

materials.

Processability

The processability of aluminum profile is excellent. In various

deformation and casting aluminum alloys, and in the various states

after the production of these alloys, the machining characteristics

have changed greatly, which requires special machine tools or

technologies.

Formability

The allowable deformation is controlled by specific tensile

strength, yield strength, ductility and corresponding processing

hardening rate.

Recyclability

Aluminum has high recovery, and the characteristics of recycled

aluminum are almost the same as that of primary aluminum.

Product Photos:

Welcome to visit our company !

Choose us & contact us !