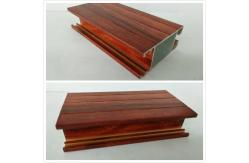

Wood Grain Imitating Finish , Strong Adhesion , Strong Impact Resistance , Durable

|

|

Wood Grain Imitating Finish , Strong Adhesion , Strong Impact Resistance , Durable

1.Description:

2.Introdution of product:

The wood grain transfer profile is based on the powder spraying or electrophoretic coating, according to the principle of high temperature sublimation thermal penetration, by heating and pressing, the wood pattern on the transfer paper or the transfer film is quickly transferred and penetrated to the profiles which have been sprayed or electrophoretic. The production of wood grain profile clear texture, strong sense of three-dimensional, better reflect the natural feeling of wood grain, is an ideal energy saving and environmental protection material instead of traditional wood. Wood grain has strong adhesion to aluminum, which is non-toxic, odorless and easy to clean. Product lines clear and realistic, strong sense of three-dimensional, decorative effect is good, there is a return to nature, return to nature's visual effect. The coating on the surface of the aluminum profile can not volatilize or oxidize in the air without any pollution to the environment. The dirt deposited on the spray surface can be restored to its original luster and appearance after being washed.

3.Process:

1. suitable for large area or special-shaped substrate

(1) select the substrate that has been sprayed or electrophoretic.

(2) use wood grain heat transfer paper to wrap the transferred substrate, and use the heat resistant adhesive tape to fix the interface of the paper, so as to prevent grained heat transfer paper from loosening. (Note: the front side of wood pattern heat transfer paper should be pasted with the transferred substrate.

(3)then set up the high temperature resistant and well sealed plastic plastic bag on the base material which has been wrapped by the wood grain heat transfer paper, and then vacuum from the two ends of the plastic bag until the plastic bag is fully and effectively cling to the base material. The negative pressure of vacuum should be adjusted according to the characteristics of the transferred substrate and the negative pressure that the plastic bag can bear, usually between 0.3 and 0.8Mpa. (Note: the purpose of using plastic bags is to force the wood grain hot transfer paper to be fully and effectively pressed on the base material by the negative pressure.

(4) the base material that has been wrapped is sent to the oven to bake. The height of the baking temperature and the length of the time should be adjusted according to the characteristics of the substrate, the depth of the transfer texture and the specific performance of the oven. The temperature of the transfer is usually 160~180 centigrade and the time is 5~8 minutes.

(5) remove the transferred substrate from the oven and pull out the plastic bag from one end of the transferred substrate (Note: this plastic bag can be reused), tearing down the hot transfer paper, and cleaning the surface.

2. suitable for flat substrate

(1)select the substrate that has been sprayed or electrophoretic.

(2) lay the front side of the heat transfer printing paper with the front side of the transferred substrate.

(3) the flat heat transfer printing machine is pressurized and heated, usually the transfer temperature is 160~180 degrees, and the time is 18~25 seconds.

(4) tear down the heat transfer paper, use PET thermal transfer film transfer: apply to the special shaped substrate.

(5) the PET heat transfer film is used to wrap the transferred substrate, and the PET heat transfer film is sealed into a tubular bag by an ultrasonic sealing machine. (Note: the front side of the PET thermal transfer film should be pasted with the transferred substrate.

(6) vacuum the two ends of the tubular PET heat transfer film bag until the PET thermal transfer film can fully and effectively cling to the substrate. The negative pressure of vacuum should be adjusted according to the characteristics of the transferred substrate and the negative pressure that the PET heat transfer film can bear, usually between 0.3 and 0.8Mpa.

(7) the base material that has been wrapped is sent to the oven to bake. The height of the baking temperature and the length of the time should be adjusted according to the characteristics of the substrate, the depth of the transfer texture and the specific performance of the oven. The temperature of the transfer is usually 160~180 centigrade and the time is 5~8 minutes.

(8) remove the base material that has been transferred from the oven and remove the PET heat transfer film by hand or mechanical blow (that is, blowing the PET heat transfer film tube in the way of blowing gas).

Please tell us the information below, and we will give the best

suggestion to you! Choose us & contact us! |

||||||||||||||||||||||||||||

| Product Tags: kitchen cabinet profiles square aluminum profile |

|

Heat Transfer Surface Wood Grain Aluminium Profile Section For Construction |

|

6.0 Meters Wood Finish Aluminium Profiles For Windows And Doors Frame |

|

2.0mm Thickness Wood Grain Aluminium Profile For Windows And Doors |

|

3D Touching Wood Finish Aluminium Profiles Heat Transfer For Outdoor |

|

6063 T5 Shavings 3D Wood Finish Aluminium Profiles |

|

6063 Wood Finish Aluminum Profiles Square Hollow Pipe For Decoration |