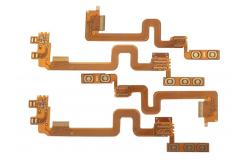

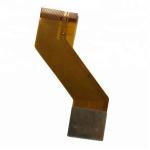

Heat retardant Flexible pcb Polyimide with SMT service FPCB board

|

|

Heat retardant Flexible pcb Polyimide with SMT service FPCB board

Number of Layer: Single sided Board material: PI Copper thickness: 1OZ Surface finishing: Immersion gold

Flexible Printed Circuit Board (abbr. FPCB) .

FPCB is minimization, slimness, high technology for whole digital products which are getting smaller, slimmer. Compare with the rigid printed circuit board , FPCB has the following advantages

1. Light, thin, short, small, flexible structure, can be bent, curled, folded, and three-dimensional assembly, adapter can replace a lot of parts, easy to use maximum available space, making electronic products become more slim in appearance, widely used has a small, lightweight and mobile requirements of all kinds of electronic products.

2. High heat resistance, can produce higher density and finer pitch products to meet the high density interconnect between the components and the high stability requirements, so that a larger increase the quality of the signal output.

3. Can be wound transfer roller processing methods (Roll-to-Roll), easily automated, mass production,improve production efficiency.

FPC Process Capability

Application For Whole Digital Products

Packing and Delivery Packing1. Firstly hermetic plastic bag fill with products, Delivery1. It would take 7-9 days to mufacture it after deposit received.Production time would depend on your drawing and process plan. 2. DHL,FedEx, UPS delivery. It is faster than vessel.Barely deliever it by vessel.

|

|||||||||||||||||||||||||||||||||

| Product Tags: flexible pcb board flexible printed circuit boards |

|

FCCL 105um Copper ENIG Flexible Printed Circuit Board |

|

3OZ 0.6mm Thickness Copper FCCL Flex Circuit Boards |

|

105um Copper 4mm Thickness Immersion Gold Fr4 Flex PCB |

|

Multilayer Flexible Printed Circuit Board FPC Polyimide Immersion Gold Surface |

|

FPC Flexible Printed Circuit Board Assembly 1-4 Layers PCB Polyimide For Stiffener |

|

Reliable 2 Layer Flexible Pcb Prototype , Laser Cut Flex Printed Circuit Board |