30TPD Automatic Pyrolysis Plant For Waste Tyre/Plastic Recycling To Fuel Oil

|

|

30TPD Automatic Pyrolysis Plant For Waste Tyre/Plastic Recycling To Fuel Oil

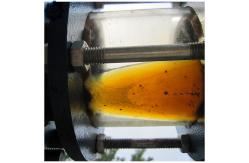

Pyrolysis machine, also called pyrolysis plant/pyrolysis unit/pyrolysis device, is a popular recycling machine that can recycle and convert solid&hazardous waste like tires, plastic, oil sludge, coal tar oil, aluminum plastic composite materials, etc. into valuable products namely oil, syn-gas and char(carbon black), ingot, etc. 1. The Raw Material For Pyrolysis Machine

2. Pyrolysis plant specification 3.The available fuel for pyrolysis processing

4. End product percentage and useage( Example : raw material is tyre)

5. advantage and main technical characteristics of Pyrolysis machine 1. High oil output rate 45%--55% with special catalyst formula and high tech . 2. Rapid condensers and large cooling area,assure you get much more and higher quality oil. diversiform cooling system can be choose according to client's willingness 3. Dust-removing device -four levels dust processing system make sure no any population and the output smoking is the spray .more environmental protection. 4. Double tail-gas recycling and burning system, saving energy. 5. Q245R boiler plate, high temperature resistance, thickness reaches 14mm—16mm,guarantee 4-7 years service lives. and optional plate is Q345R 6. OptionalAuto feeder and carbon black discharge elevator, high automation, saving time and labors. 7. Eco-friendly and no any population, environmental protection 6.Machine 3D drawing flow chart and working processing

Operation process of waste plastic pyrolysis plant 1.The size for the equipment Picture of Waste Tyre Recycling To Oil Pyrolysis Machine

|

|

Full-Auto Pyrolysis To Fuel Equipment For Waste Plastic Tyre Recycling |

|

High Oil Yield Factory Price 10 Ton Per Day Waste Tyre Rubber Pyrolysis To Diesel Fuel Oil Plant |

|

Huge Profit Waste Tire Tyre Plastic Recycling Production Line To Fuel Oil |

|

20ton Full-Scale Pyrolysis Plant For Waste Plastic Recycling To Energy Oil |

|

50ton Scrap Tyre Rubber Powder Pyrolysis Production Line For Fuel Oil |

|

Waste Treatment To Energy Waste Tire/Plastic Recycling Pyrolysis Machine |