RAL1007 daffodil yellow electrostatic thermoset powder coating with excellent dimensional stability.

|

|

RAL1006 Maize yellow cost effective electrostatic thermoset powder coating

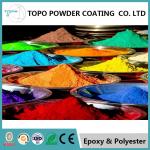

Thermoset materials are used for the majority of powder coating processes because they can provide a surface layer that is both durable and decorative. Most thermoset powders have a molecular weight lower than that of thermoplastic materials and higher than that of liquid coatings. Thermosets are solid resins that, when heated, melt, flow, and—unlike thermoplastics—can crosslink with one another or other reactive substances to form compounds with higher molecular weights. After curing, a thermoset coating remains thermally stable, meaning it cannot be melted back into a liquid from further heating.

In a powder coating system, the more brittle thermoset resins can be broken up into a very fine powder that can then be fabricated into an exceptionally thin, paint-like film. This film exhibits chemical and physical properties comparable to those of liquid-based coatings. In addition, advancements in thermoset technology have continuously increased the versatility of this material group, allowing for more customization options. Many standard thermoset materials can now be chemically altered to provide the specific characteristics required for a given application.

Thermoset Pros

Thermoset Cons

|

||||||||||||||||||||||||||||||||||||||||||

| Product Tags: electrostatic powder coating automotive powder coating |

|

TGIC Free Polyester Powder Coating Paint RAL 1021 Colza Yellow Color |

|

RAL 1019 Electrostatic Powder Coating , Architectural Aluminium Polyester Powder Paint |

|

Aluminum Pipeline Powder Coating , RAL 1017 Saffron Yellow Eco Powder Coating |

|

RAL 1015 Light Ivory TGIC Polyester Powder Coating , Durable TGIC Powder Coating |

|

Pebble Grey Ral 7032 Powder Coating , Polyester Textured Powder Coat Paint |

|

Pure Polyester TGIC Architectural Powder Coatings , RAL 1012 Lemon Yellow Powder Coat |