MF Magnetron Sputtering PVD Vacuum Coating Machine, TiN MF Sputtering Deposition Unit

|

|

PVD MF Magnetron Sputtering Coating Machine, MF Sputtering System, TiN MF Sputtering Deposition Unit

MF Mangetron Sputtering Coater RT1215-SPMF is d esigned for copper, alumunium, plastic, metal circuit board conductive film layer plating. It can condense Nano thin film on substrates. Except Ag sputtering, it can also deposit Ni, Au, Ag, Al, Cr, SS316L.

The RTSP1215-MF machine is installed with 2 pairs of MF sputtering cathodes on chamber, and 1 set of Anode Layer Ion source for plasma bombardment cleaning before PVD film deposition.

Ion source is original from Gencoa company, the properties:

1. Optimized magnetic fields to produce a collimated plasma beam at standard sputtering pressures 2. Automated regulation for the gas to maintain constant current & voltage – multi-gas auto control 3. Graphite anode and cathode to protect the substrate from contamination and provide long-life components 4. RF standard electrical insulation on all ion sources 5. In-direct cooling of anode and cathode – quick switching of parts 6. Easy switching of cathode parts to provide multiple magnetic traps for lower voltage operation, or a focused beam 7. Voltage regulated power supply with gas adjustment feedback to maintain same current at all times

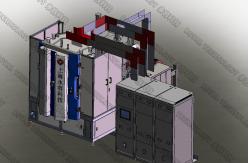

RTSP1215-MF MF Sputtering Coating Equipment Layout

RTSP1215-MF MF Sputtering Coating Equipment Applications:

1. Available on substrates of: Plastic, Polymer, Glass and ceramic sheets, Stainless steel, Copper sheet, Aluminum board etc.

2. To generate Nano film like: TiN, TiC, TiCN, Cr, CrC, CrN, Cu, Ag, Au, Ni, Al etc.

RT1215-SPMF MF Sputtering Coating Equipment Design Features:

1. Robust design, good for limited room space 2. Easy access for maintenance and repair 3. Fast pumping system for high yield 4. CE standard electrical enclosure, UL standard is also available. 5. Accurate fabrication workmanship 6. Stable running to guarantee high quality film production.

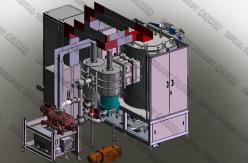

Cylinder or Planar MF Sputtering Machine working status

RT1215-SPMF MF Sputtering Coating Equipment Specifications:

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions. |

|||||||||||||||||||||||||||||||||

| Product Tags: small pvd coating machine vacuum coating plant |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

PVD Magnetron Sputtering Coating Machine For Automotive Hubs |