Au Gold Glass Slide Mangetron Sputtering System Pvd Process 1 Door Chamber

|

|

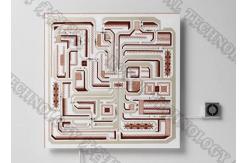

Au Gold Glass slide Mangetron Sputtering System / PVD Au Gold Sputtering Coating Machine

Gold Coated Glass Slides and Silicon Wafers use the PVD process of DC magnetron sputtering to deposit Au metal thin film layer on substrages, like: glass slide, Silicon wafers, metal jewelry, steel, glass and ceramic wares etc. Except Au sputtering, it can also sputter Ag Silver, Cu Copper, Al Aluminum, Cr Chrome, SS stainless steel 316L etc. for conductive film or high luxury decoration applications. The gold sputtering layer features: 1. Ti or Cr Adhesion layer between substrates and gold layer is strong recommended to improve the adhesion; 2. The Gold layer thickness: ranges from 10~100nm based on different optical applications. 3. The roughtness (RMS - root mean square) < 40Å is expected for most of the applications. For certain scanning probe applicatons a lower roughness might be required, generally 1.5 ~ 4 nm. 4. Gold sputtering layer surface purity: a clean surface is required for applications that employ gold surface modifications. Depending on the PVD process used, level of vacuum in the system, original purity of the gold source, and history of metals used in the particular system the level of gold thin film purity can vary greatly.

As an advanced coating technology which can reduce up to 80% production cost and the most important is the great surface finishing.

Au Gold Mangetron Sputtering System Hightlights:

ROYAL Technology Ag gold sputtering machine is available for manufactures who are looking for high productivity and simple coating solutions.

Robust design, large batches, fast cycle, flexible coating processes are the basic design concepts ROYAL Team has been pursuing.

Au Gold Mangetron Sputtering System Models

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering equipment vacuum deposition equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

PVD Magnetron Sputtering Coating Machine For Automotive Hubs |