Gold, silver and copper Ceramic PVD Sputtering Deposition Machine ,

|

|

Au Gold Sputtering Deposition Equipment, Silve/Gold PVD Deposition Machine, Conductive Film PVD Sputtering System

Summary: The DPC process- Direct Plating Copper is an advanced coating technology applied with LED / semiconductor / electronic industries. One typical application is Ceramic Radiating Substrate. Cooper conductive film deposition on Aluminum Oxide (Al2O3), AlN substrates by PVD vacuum sputtering technology, compared with traditional manufacturing methods: DBC LTCC HTCC, much lower production cost is its high feature. Royal technology team assisted our customer to developed the DPC process successfully with PVD sputtering technology.

Keywords: Ceramic sealing parts, DPC process, Copper PVD Sputtering system, LED Ceramic Chips With Cooper Plating, Al2O3, AlN Ceramic Circuit Boards, Al2O3 Plates On LED, Semiconductor

Applications of DPC: · HBLED · Substrates for solar concentrator cells · Power semiconductor packaging including automotive motor control · Hybrid and electric automobile power management electronics · Packages for RF · Microwave devices

DPC Technology Performance Various substrate materials: Ceramic (Al3O2, AlN), Glass, and Si

Features:

Technical Specifications

1. Ultimate Vacuum Pressure: better than 9.0*10-5 Pa;

3. Pumping down Time: from atm to 1.0×10-3 Pa≤15 minutes ( room temperature, dry, clean and empty chamber) 4. Deposition source: Gencoa magnetron sputtering cathodes, steered arc cathodes, Ion source 5. Operating Model: Full Automatically /Semi-Auto/ Manually 6. Heating: from room temperature up to max. 500℃, 9. Ion source for PECVD and PA PVD process.

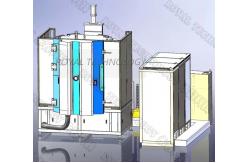

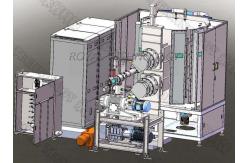

The vacuum coating machine contains key completed system listed below:

1. Vacuum Chamber

Inner Height: 1500mm 1.2 Material: Vacuum Chamber SUS304 Door and flanges SUS304 Chamber strengthen structure: SS41 mild steel, with painted finishing surface treatment. Chamber chassis SS41 mild steel with painted finishing surface treatment. 1.3 Chamber Shield : SUS304 1.4 View Window: 2 on door 1.5 Vacuum Chamber Venting Valve (including silencer) 1.6 Door: SUS304 material

2. Roughing Vacuum Pumping System:

3. High Vacuum Pumping System: Magnetically Suspension Molecular Pump - 2 sets Suppliers: PLC: Mitsubishi + Touch Screen (Made in China) Electronic Components: SCHNEIDER,OMRON. Safety Protecting System: Numerous safety interlocks to protect operators and equipment ( water, current gas, temperature etc.) Coating Processes System: Process Automation & Control. 4.1 Main circuit: None-fuse breaker switch, electromagnetic switch, C/T in series type 4.2 Power Supply: DC/MF sputtering power + DC Arc power + Bias Power Supply 4.3 Deposition control system 4.4 Operation System: Touch Screen + PLC, recipe control and data logging, Auto shutdown, auto evacuation, auto coating 4.5 Measuring System Vacuum Pressure : Vacuum Gauge: Pirani + Penning gauge + Full range vacuum gauge -- Europe brand Temperature measuring device: Thermo-couple 4.6 Alarm System: Compressed air pressure , Cooling water flow, Mis-operation 4.7 Power Load Indicator: Voltage indicator and load current indicator

5. Deposition System 5.1 Deposition source: Sputtering cathodes+ Arc sources + Ion Source 5.2 Deposition material: Copper, Aluminum, Chrome, Silver, Gold,

SS, Titanium etc. 6. Sub-System 6.1 Air Compressed Valve Control System 6.2 Cooling Water System:Water flow pipe and switch valve system

7. Working Environment Compressed Air: 5~8kg/cm2 Cooling Water: Water-In Temperature: 20~25℃, 200 Liter/min,

Power: 3 Phase 380V 50Hz(60Hz), 130kVA, average power consumption: 60KW Installation Area: (L*W*H)4400*3200*2950mm Exhaust: Vent for mechanical pumps

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions. |

| Product Tags: small pvd coating machine vacuum coating plant |

|

Ag Silver Sputtering Deposition Machine-RTSP-Ag1215 |

|

Metal Jewelry PVD Vacuum Coating Machine , IPG Gold Plated With Magnetron Sputtering |

|

Zamak Rose Gold Handle Vacuum Arc Ion Plating System , Steel Vacuum Plating Machine , Zinc Alloy PVD Plating Equipme |

|

Metal Jewelry PVD Vacuum Coating Machine , IPG Gold Plated With Magnetron Sputtering |

|

Rose Gold PVD Gold Plating Machine For Watch Metal Part |

|

PVD Nickel Plating Machine, PVD Chrome Sputtering Deposition System |