Plastic Metalizing PVD Coating Service , Thermal Evaporation Coating, Environmentally Friendly Coating

|

|

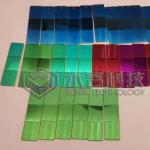

Plastic Metalizing Coating Service / Plastic PVD Thermal Evaporation Coatings

Royal technology has developed and built the whole supplies chains for various of plastic metalizing service. PP, PE, PVC, PET, ABS, PC, PC+ABS etc.

PVD (Physical Vapor Deposition) process of “Vacuum Thermal Evaporation or Vacuum Thermal Deposition” as an advanced coating technology to replace the traditional water-electroplating surface treatment methods. This coating technology is widely used for surface decoration and functional applications as applied to standard substrates listed below:

1. Decorative Coatings: ABS, PP, PC, PET, PMMA to deposit a thin

film, high reflective, metallic like coating on toys, fashion and

consume jewelry accessories, Christmas tree decorations, balls,

buttons, shoes, mirrors.

Vacuum Coating VS Traditional Electroplating

Finishes are deposited using an environmentally friendly green

process;

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions. |

| Product Tags: metal coating services thin film coating services |

|

PVD Coating Service Vacuum PVD IP Gold PVD Copper PVD Brass IP Blue Decorative Coatings |

|

Sapphire PVD Titanium Nitride Coating Service, MF Sputtering Sapphire PVD Coating |

|

Glassware PVD decorative coating service |

|

Glassware PVD gold coatings, 2-sides PVD gold platings on glass products |

|

PVD navy blue, PVD baby-blue, PVD Sapphire coatings on SS sheets, PVD blue coating machine |

|

Decorative PVD green color, brass green coatings on Stainless steel panels |