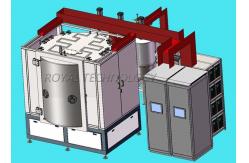

Arc Evaporation Chrome Plating Equipment , Hand Shower Silver Pvd Coating Equipment

|

|

PVD Chrome Plated Shower Head and Tubes Coating Equipment, PVD Chrome Plating Machine, Hand Shower Silver Color Plating

PVD Chrome plating is to improve the product's surface performance, more durability and wear resistance, anti-corrosion.

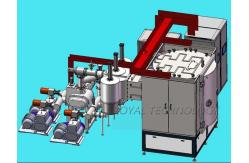

Royal Technology provides you not only the coating machine

but the total coating solutions, turnkey-project service is

available.

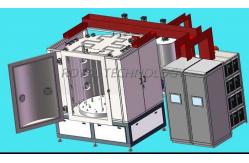

ArC PLATING MACHINE PVD coating equipment mainly for decoration coatings on the metal, ABS parts. The ranged colors are silver, black, gold. When introducing different reactive gas and target materials the colors are changing slowly, during the deposition changing period, to get the idea desired colors.

This is operated by changing different coating parameters and process. Coating processes to deposit every each color is stored in PLC software recipes, totally 10 recipes are available. So that the AUTO COATING model is possible after the recipes is logged in. The full automatically operation is very helpful for primer PVD operators.

The advantages:

1. Economically efficient, generating the thinnest, most uniform

coating films; 5. Fast deposition rates and high quality surface finishes.

Technical Performance

4. Coating Product Samples by Arc Vacuum Coater

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: hard coating machine pvd coating equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Hardware Decorative Pvd Gold Plating Machine ZrN Light Gold Ion Plating System |

|

Bathroom Fittings Gold Plating Machine Taps TiN Gold ZrN Gold PVD Plating Machine On Brass Faucets |

|

Stainless Steel Fruit Dishes Ion Plating Machine / TiN Gold Steel Dishes Vacuum Coating Machine |

|

Brass Taps Metal House Bathroom Fittings Gold Plating Machine TiN Gold Coating On Taps Faucets |

|

Brass Alloy Faucet IPG Light Gold Coating Machine , Vertical Orientation ZrN Gold Plating Equipment |

|

Bathroom Fittings Gold Plating Machine Taps TiN Gold ZrN Gold PVD Plating Machine On Brass Faucets |