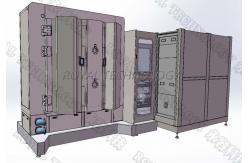

DC Magnetron Sputtering Coating Machine , Unbalanced Planar Sputtering Coating System

|

|

DC Magnetron Sputtering Coating Machine / DC Sputtering System

Magnetron Sputtering Models: DC Sputtering, MF Sputtering, RF Sputtering

What is DC Sputtering?

DC Sputtering mainly used to sputter pure metal targets like: Chrome, Titanium, Aluminum, Copper, Stainless Steel, Nickle, Silver, Gold for high conductive films.

DC Sputtering is a Thin Film Physical Vapor Deposition (PVD) Coating technique where a target material to be used as the coating is bombarded with ionized gas molecules causing atoms to be “Sputtered” off into the plasma. These vaporized atoms are then deposited when they condense as a thin film on the substrate to be coated.

DC Sputtering is the most basic and inexpensive type of sputtering for PVD metal deposition and electrically conductive target coating materials. Two major advantages of DC as a power source for this process is that it is easy to control and is a low cost option if you are doing metal deposition for coating. DC Sputtering is used extensively in the semiconductor industry creating microchip circuitry on the molecular level. It is used for gold sputter coatings of jewelry, watches and other decorative finishes, for non-reflective coatings on glass and optical components, as well as for metalized packaging plastics, car mirrors, car lighting reflectors, car wheel and hubs etc.

DC Magnetron Sputtering Coating Machine Performance 1. Ultimate Vacuum Pressure: better than 5.0×10-6 Torr. 2. Operating Vacuum Pressure: 1.0×10-4 Torr. 3. Pumpingdown Time: from 1 atm to 1.0×10-4 Torr≤ 3 minutes ( room temperature, dry, clean and empty chamber) 4. Metalizing material (sputtering + Arc evaporation): Ni, Cu, Ag, Au, Ti, Zr, Cr, TiN, TiC, TiAlN, CrN, CrC, etc. 5. Operating Model: Full Automatically /Semi-Auto/ Manually

DC Magnetron Sputtering Coating Machine Structure The vacuum coating machine contains key completed system listed below: 1. Vacuum Chamber 2. Rouhging Vacuum Pumping System (Backing Pump Package) 3. High Vacuum Pumping System ( Magnetically Suspension Molecular Pump) 4. Electrical Control and Operation System 5. Auxiliarry Facility System (Sub System) 6. Deposition System: DC sputtering cathode, DC power supply, Bias Power Supply Ion source for optional

DC Magnetron Sputtering Coating Machine Specifications

We have more models for your selection!

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering equipment vacuum deposition equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

PVD Magnetron Sputtering Coating Machine For Automotive Hubs |