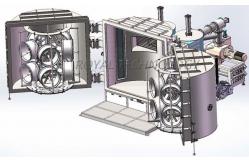

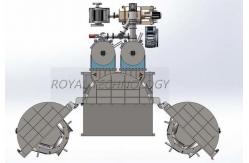

Car Aluminum Alloy Wheels PVD Chrome Plating Machine, Automotive wheel Chrome Plating

|

|

PVD Hard Chrome Auto Wheel Coating Machine, Auto Wheels PVD Chrome Vacuum Metallizer, Sputtering Vacuum Coating Machine

General Information

The PVD Vacuum Hard Chrome coating process has been used in the automotive industries for decades. Sputtering Chrome/Aluminum on Aluminum alloy rims is a standard application due to its 100% environmentally friendly process and resistance to pitting or peeling off like traditional water-electroplating. The high abrasion resistance coating forms a durable film that greatly enhances the car rim’s lifetime. For these reasons and ease of use and reliability the PDV hard chrome coating is welcomed by the automotive factories.

RTSP2022 Advantages:

The coating colors:

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering equipment vacuum deposition equipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

PVD Magnetron Sputtering Coating Machine For Automotive Hubs |