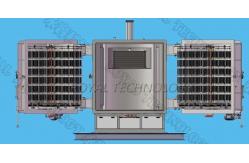

Car Mirror Magnetron Sputtering Coating Machine , Chrome Mirror PVD Sputtering Machine

|

|

Automotive Mirror Magnetron Sputtering Coating Machine / PVD Chrome Car Mirrors Sputtering System

Magnetron Sputtering Coating Technology enables for mirros high throughput demand due to its fast deposition rate. Unlikely the in-line coating line, the low production cost makes it possible for the entrepreneurs who are aming to start the business at a low investment.

Magnetron Sputtering Coater Key Features: Hight througput and large bath capability.Highly transparent, electrically conductive, highly reflective solar collectors, selectively reflective corrosion-proof, anti-glaring blue.

Automotive Mirror Magnetron Sputtering Coating Machine General Information Various coating processes for automotive mirrors has been developed and qualified. Chromium PVD coating onto float glass substrates as reflection layer is accomplished by DC-Magnetron sputtering. Colour appearance of the layers can be generated by introducing of reactive gases, like Argon, Oxgen and Nitrogen.

Automotive Mirror Magnetron Sputtering Coating Machine Specifications

Automotive Mirror Coating Sample:

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|

||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering machine vacuum deposition equipment |

|

Vacuum Metal Deposition Machine For Vertical Chamber Orientation And Durable Coating On Different Plates |

|

PVD Hard Chrome Plating On Aluminum Wheels , Car Wheels PVD High Glossy Chrome Coating Machine |

|

Polymer Plastic Metallization Equipment- Plasma Assistant PVD coating |

|

PVD Hard Chrome Plating On Aluminum Wheels , Car wheels PVD high glossy chrome coating machine |

|

2024 Newest developed coatings- brown color on automotive ABS articles |

|

Car Light Reflectors Coater, Automotive Head Lighting Reflectors HMDSO Coating Machine, Car light Aluminum Metallizer |