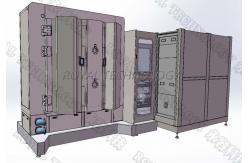

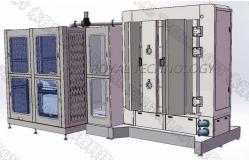

SiC Fuel Cell Module Thin Film Deposition Equipment , PECVD Magnetron Sputtering Equipment

|

|

SiC Fuel Cell Module PECVD Sputtering System / Hydrogen Fuel Cell Magnetron Sputtering Coating Equipment

SiC Fuel Cell Module Sputtering System Specifications

The SiC Fuel Cell Module Sputtering System is exclusively designed and developed for FCV vechiles application. FCV is the short name of Fuel Cell Vehicle, it is the newest technology for next generation of green cars. It can generate electrical energy continuously by electrochemical reaction between oxygen and hydrogen. It is different from the primary battery such as dry cell and rechargeable battery that needs to repeat charging. The core technology is how to generate the electrical energy with fuel cell power module through electrochemical reaction between hydrogen as fuel and oxygen. Hydrogen fuel cell as the most key important part of the power module, scientists, engineers, professors from transportation organizations and worldwide vehicles manufactures have made thousands tests and finally found the proper processing. Hydrogen Fuel Cell Power Module Sputtering System with the PECVD (Plasma Enhanced Chemical Vapor Deposition) Technology to deposit high uniformity, strong adhesion SiC thin films. The Hydrogen fuel cell sputtering machine contains ion source, balanced/unblanced sputtering cathodes; with stable and large volume vacuum pumping system. The special designed rack and jig system can take out-move in completely for a substrates convenient loading/unloading.

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering machine vacuum deposition equipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

Niobium Dioxide (NbO2) Deposition Machine-RTSP1000-Nb |