Copper DC Magnetron Sputtering Machine , Cu Thin Film Deposition Systems

|

|

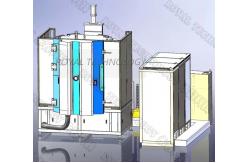

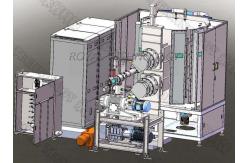

Copper Conductive Magnetron DC Sputtering Coating Machine / Aluminum Circuit Board Cu Film Plating

Copper Conductive Magnetron DC Sputtering System is for aluminum / plastic/ metal cirucit board conductive film layer plating. It can condense Nano thin film on substrates. Except Ag sputtering, it can also sputter Au gold, Ag Silver, Al Aluminum, Cr Chrome, SS stainless steel 316L etc. for conductive film or high luxury decoration applications.

Compared with traditional wet eletroplating, the PVD silver ion plating process generates the brighter and higher reflective film. The most important is the uniformity which is much better than electroplating. And the film thickness can be measured and controlled by professional " Deposition Thickness Monitor "Thus it widely used for decoration and reflection industries. The substrates are various: plastic till metal, ceramic, glass, stainless steel etc.

As an advanced coating technology which can reduce up to 80% production cost and the most important is the great surface finishing.

High Lights of ROYAL Magnetron Sputtering Coating Equipment

ROYAL Technology Silver Plating Machine is available for manufactures who are looking for high productivity and simple coating solutions.

Robust design, large batches, fast cycle, flexible coating processes are the basic design concepts ROYAL Team has been pursuing.

ROYAL Technology provides you not only the coating machine but the total coating solutions, turnkey-project service is available.

Aluminum Circuit board before PVD Sputtering

Aluminum Circuit board After Cu Sputtering

Copper Conductive Magnetron DC Sputtering Coating Machine Models

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: magnetron sputtering machine vacuum deposition equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

Metal Watches And Jewelry Gold Plating Machine With CE Certification |

|

Vacuum Flask Magnetron Sputtering System , PVD Cooper Deposition Equipment , PVD Sputtering Copper Deposition Machine |

|

Magnetron Sputtering PVD Vacuum Coating Machine IPG Blue MF Sputtering Machine |

|

PVD Sputtering Chrome Coating Machine For Car Mirrors |

|

Niobium Dioxide (NbO2) Deposition Machine-RTSP1000-Nb |