Sinter HIP Hot Isostatic Pressing Machine 320kW Power Energy Saving

|

|

High Efficient Sinter HIP Furnace Molybdenum Tungsten High Pressure Temp

Overview

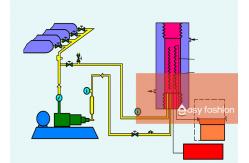

Sinter HIP furnace series are designed to integrate the functions of pressure de-waxing, TORVAC, partial pressure sintering, pressure sintering, atmosphere sintering, vacuum de-waxing, vacuum sintering, cooling and etc. Mainly use for Cemented Carbide processing such as molybdenum , tungsten and nickel etc. Horizontal design for easy loading, unloading and maintenance Automatic control during whole process To meet various working process requirements, process gases like Ar, H2, CH4 and N2 could be used to control chamber atmosphere under different pressure and temperature.

Technical specifications

Remark: Both square or cylinder inner box could be provided. Standard available pressure types are 1MPa, 6MPa, and 10MPa. Standard sizes of usable space are 300×300×1200mm, 400×400×1200mm, and 500×500×1800mm.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: metal sintering machine hot isostatic pressing machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Industrial High Temperature Sintering Furnace Plc Full Automation Control |

|

Spark Plasma Metal Sintering Furnace High Efficiency For Nanometer Materials |

|

Good Performance Cemented Carbide Sintering Sinter HIP Furnace Series Equipment |

|

MIM Vacuum Degreasing and Sintering Furnace |

|

Sinter HIP Furnace With Fast Coolilng |

|

Sinter HIP Furnace Series |