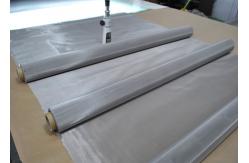

Stainless Steel Silk Screen Printing 400 Mesh 23 Um For Bottles Printing

|

|

Stainless Steel Silk Screen Printing 400 Mesh 23 Um For Bottles Printing

Description of the stainless steel screen printing mesh:

Screen printing is an inexpensive, large-area micro-manufacturing printing technology widely used in the production of electronic equipment. Screen printing can be used to print on a variety of substrates such as glass, plastic, ceramic or metal. In screen printing, the ink is pressed onto the substrate by a patterned screen with a rubber scraper. Rubber scrapers are usually made of rubber. The screen is made of a porous mesh made of a porous fabric or a stainless steel wire and tightly stretched onto a frame made of metal or wood. The micromodal image is photochemically replicated on a grid. The quality of the pebbles on the substrate is highly dependent on: the distance from the screen to the substrate, the number of fibers in the screen, the tension of the screen, the cleaning parameters of the process parameters (speed, pressure angle), the ambient temperature humidity, the air Mobile and printing

Features of stainless steel screen printing mesh :

High tension: Much higher tension than common polyester mesh and

smooth tension;

Applications of stainless steel silk screen printing mesh:

From soda bottles to semi-conductor metal meshes are often used for screen printing. Mechanical strength and wear resistance are the basic requirements for stainless steel mesh. The stainless steel mesh must support the high tensile stress due to the rapid passage of the squeegee as it forces the high viscosity ink through the mesh. For this type of application, a 316 wire with a diameter of 15 microns is typically used for the weft of the wire mesh. Type 316 stainless steel resists corrosive inks and cleans the upper, which are sandwiched in the gaps where the warp weft yarns intersect. Screen printing applications range from traditional labels for pharmaceutical and food bottles to advanced applications required by the semiconductor industry. Here, ultra-fine woven metal mesh, which is indispensable for dimensional accuracy and printing definition, is used for printing printed circuit masks and marking liquid crystal displays and photovoltaic solar panels. Ink-containing stainless steel micro-mesh is present in the inkjet cartridges, which ensure fluidity and proper distribution of ink in front of the nozzle.

Specification:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: stainless steel mesh roll stainless steel mesh fabric |

|

Ultra Fine Stainless Steel Screen Printing Wire Mesh |

|

SS 316 316L Stainless Steel Screen Printing Mesh For Filtration |

|

High Precision 635 Mesh 304 Stainless Steel Screen Printing Mesh |

|

Ceramic Industry 1.22meters Wide Stainless Steel Printing Screen 250 270 300 Mesh |

|

Customized Thickness Plain Weave 325 400 Stainless Steel Screen Printing Mesh |

|

2.2 Meters Width Monofilament Fine Woven Wire Mesh Plain Weave |