Hardness 90 1500*500 1120kg/M³ Epoxy Tooling Board

|

|

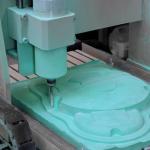

Medium Density Less dust CNC Process Polyurethane Plank designed for sheet metal stamping fixture

Product Description

LH -5112 is a high quality 1120kg/m³ epoxy tooling board. This rigid epoxy tooling block is recommended for demanding applications for CNC machining of highly accurate models, patterns or masters as well as production tools/moulds. Epoxy is the tooling board of choice for high temperature applications and is essential when making prepreg composite moulds or components where, at elevated temperature, this epoxy pattern material will not inhibit the cure of prepregs in the same way that polyurethane (PU) board will.

In today's world rapid growth of composite materials industry, polyurethane die plate is also more and more in CNC machining die and use. Polyurethane panels are superior to epoxy in many properties and can produce high precision moulds. Moulds made from polyurethane moulds remain accurate in size after many years of storage because they do not shrink over time and are not affected by moisture. In recent years, with the demand of end customers for high quality, in order to improve economic benefits, polyurethane board has become a trend. In order to greatly save cost, different products can be made at the same density, and products of this quality can also be made at the same hardness. Another trend is to use machined epoxy mould paste. It is formed by a mixture of two parts AB and 1 to 1, which is then CNC processed, and the mold paste allows the use of very low density foam to fill the plug or the mold's internal volume. The core of the foam is covered with tool paste. After curing, the epoxy shell is CNC machined to form a very dense, very durable, high-temperature mold surface that can maintain a vacuum and withstand multiple draws.

Key Characteristics

KEY PROPERTIES

USES

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 1500*500 Epoxy Tooling Board Hardness 90 polyurethane model board |

|

High Precision Modeling Boards MB-0600 50-55D Brown Density 0.60cm/Cm3 |

|

MB-0670 60-65D 0.67cm/Cm3 Epoxy Tooling Board Cubing Models Patterns |

|

35mm Hardness 75-85D Epoxy Tooling Board For Foundry Pattern Plates Hammer Tools |

|

Light Green 1.25g/Cm3 Epoxy Tooling Board For Foundry Pattern Plates Foundry Core Boxes |

|

Orange Color 1.20g/Cm3 Polyurethane Model Board 100mm For Pattern Plates And Core Boxes |

|

Olive 1.40g/Cm3 Polyurethane Tooling Board For Machining Concave Convex Model And Fixture |