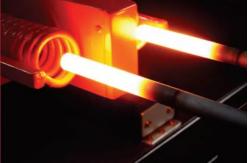

Customized Induction Heating Machine Medium Frequency For Steel Bar / Rod Forging

|

|

Customized Induction Heating Machine Medium Frequency For Steel Bar / Rod Forging

Introduction

The principle of high frequency induction heating is that apply high frequency alernating current to a conduct that is curled to cyclic (normally copper tube) to produce flux, then put the metal to this area to make the flux to run through it, and eddy current will be generated in the deriction of self-capturing with flux(rotary current), the induced current then generates heat under the influence of the eddy current, so this heating method is called induction heating. hence, metal and other objects under heated can be heated without contact. at this moment, the character of the eddy current relies in that the induction heating on the object nearby the coil is outwardly strong but inwardly weak. with this principle. this heating body can be concentratedly heated where needed to achieve instantly effect, thereby the production output and work capacity are both improved.

Product Description

1. Induction Melting Furnace Equipmemt can be used for the melting of steel, stainless steel, brass,cooper,gold and so on. 2. Because of the stirring effect which caused by the magnetic force, the melting pool can be stirred during the melting course to ease the floating of the flux and oxides to produce high quantity casting parts. 3. Wide frequency range from 1KHZ to 20 KHZ, working frequency can be designed by changing the coil and compensating capacitor according to the melting material, quantity, stirring effect desire, working noise, melting efficiency and other factors. 4. Compared with SCR medium frequency furnace, it can be energy at least 20% and up. 5. Small and light, a lot of modes can be selected to melt different amount of metals. Not only it is suitable for the factory, but also suitable for the colleges and researching companies to used. 6. 24 hours non-stop melting ability. 7. It’s easy to change melting furnace to different capacity, different materials,different way of pouring out, to suitable for all kinds of requirements.

Specifications

1. For more detail informations, please contact us. 2. We also have the type of 110 V, if you need, we can customized to you. 3. This machine can't be used with a plug, it need a wire to connect the machine to power line directly (the cross-sectional area of power line must be larger than 6 square milimeters.) 4. We also sell the indutrial water chiller for this JL-15 induction heater, if you need, please send inquiry to us. 5. We can also make customized heating coil, the shape and diameter is determined by the workpiece you will process. If you make customized heating coil, please tell us the detail workpiece information.

Function

1. Brazing, Welding, Soldering 2. Melting(high power) 3.Forging Molding

In-sale service:

After-sale service:

FAQ:

1. who are we?

3.Is your goods has ISO9001 or CE certificate ? Yes, all our goods has ISO and CE certificate. All machines are high quality goods.

Our Company:

|

|||||||||||||||||||

| Product Tags: 50Khz Induction Heating Machine Steel Rod Forging Induction Heating Machine Medium Frequency Induction Heating Equipment |

|

120 KW Electric Induction Heating Machine Forging Furnace for Bolt Nut Hammer Forging Core Component |

|

Energy Saving Environmental protection High Frequency 25KW Induction Heating Equipment |

|

Aluminum Foil Induction Sealing Machine For Bottle Heat Sealer Max Fluctuating Power 30KW Easy Operation Good |

|

70kw Induction Furnace With Cable Parts And Electromagnetic Induction Heating Coil |

|

30KW Portable High Frequency Induction Heater For Copper Gold Silver Melting |

|

25KW 30 - 80 KHz Induction Heating System With Timer Control |