BS EN 367 80 kW/m2 Protective Clothing Heat Transmission Tester

Introduction:

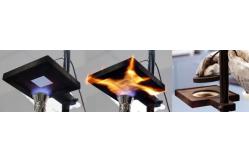

A new term heat transfer index (HTI) has been introduced to avoid

confusion with the thermal protective index (TPI) or other terms

used in previous versions of this test. Heat transfer index is

calculated from the mean time in seconds to achieve a temperature

rise of 24±0.2℃ when testing by this method using a copper disc and

a starting temperature of 25±5℃. The heat transfer index provides a

method of grading materials which does not imply that the material

tested will give any precise protective time under actual use

conditions.

Standards:

ISO 9151——Protective clothing against heat and flame --

Determination of heat transmission on exposure to flame

BS EN 367——Protective clothing. Protection against heat and fire.

Method for determining heat transmission on exposure to flame

Features:

1. The apparatus is designed and manufactured according to EN 367

and ISO9151 standards.

2. The apparatus consists of the burner, the cover sheet and the

specimen holder with copper calorimeter.

3. The cover sheet and the specimen holder are controlled via

pneumatic transmission which is automatically controlled by

software.

4. A horizontally oriented test specimen subjected to an incident

heat flux of 80KW/m2 from the flame of a Meker burner beneath it.

5. The heat passing through the specimen is measured by means of a

small copper calorimeter on top of and contact with the specimen.

6. The time to record a temperature rise of 12 or 24℃ in the

calorimeter is recorded in seconds.

7. The calorimeter-cooling device shorten the test time.

8. The mean result for the three test specimens is calculated as

the HTI.

9. The calibration of heat flow density of 80 kW/m2 is performed

automatically by software.

Technical Parameters:

1. The tester is consists of a control box and stainless steel test

gantry;

2. The copper calorimeter is made from 99% copper; diameter 40mm,

thickness 1.6mm, weight 18g; constantan thermocouple;

3. There is 1.6mm thick copper sample support frame; the size is

150mmx150mm, the middle hole of 50mm x 50mm;

4. Aluminum calorimeter; dimensions of 149mm x 149mm; thickness of

6mm; intermediate pore size 90mm; weight 264 ± 13g;

5. The specimen support frame is made of stainless steel; And the

sample distance is 50mm from the burner mouth;

6. The tester is quipped the imported Meckel burner from USA; the

burner orifice diameter is 38mm ± 2mm;

7. Inlet flow control valve precisely adjust the flame to burn

calories

8. Pressure gauge and pressure regulator is imported brands;

9. The metal plate is placed between the burner and heat the

sample, can be freely moved away;

10. Timer accuracy is 0.1s;

11. The sample size 140mmx 140mm;

12. Equipped with a metal plate; The size is 140mm x 140mm;

13. PLC and touch screen intelligent control system; the

system automatically calculates the caloric value;

14. The system of automatic ignition, automatic timing;

15. The test data is automatically saved and retrieval system, the

test report can be printed freely;

16. Thermocouple accuracy is 0.1 ºC;

17. The test table size: 650mm x 350 mm x 650mm

18. Power supply 220V 50 / 60Hz

| Standards | ISO 9151,BS EN 367 |

| Sample size | 140mmx 140mm |

| Timer accuracy | 0.1s |

| Equipped with a metal plate | The size is 140mm x 140mm |

| Thermocouple accuracy | 0.1 ºC |

| The test table size | 650mm x 350 mm x 650mm |

| Power supply | 220V 50 / 60Hz |

| Control mode | PLC and touch screen intelligent control system |

Certification

Customer Feedback