Pre - Crimped Woven Architectural Wire Mesh Panels With Versatile Spine Frame

|

|

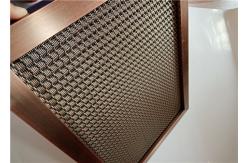

Pre-crimped Woven Wire Mesh With Versatile Spine Frame For Architecture Usage

1. Introduction To Pre-crimped Woven Wire Mesh:

1. Pre-crimped woven wire mesh is a kind of special decorative metal fabric. It is cannot be folded no matter in the horizontal direction or the vertical direction. the pre-crimped wire mesh panel have firm and durable structure. It also has bright and beautiful surface. 3. With versatile types and structures, they are pre-crimped mesh fabric are widely used in the constructions, such as facade cladding in the office buildings, handrail and

balustrade in the balconies.

2. Specification

1. pattern design support according to the application

3. Images of the woven wire mesh with versatile spine frame

Features:

1. Rigid and firm structure. The decorative wire mesh panels cannot

be folded, it is used in a panel. special structures can be customized. which can not only supply decorative functions, it can also secure people from danger.

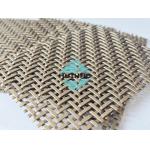

4. Patterns of the pre-crimped woven with mesh for architectural usage

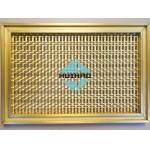

5. Application of the architectural woven wire mesh

• Space divider.

• Wall decoration.

• Ceiling decoration. • Facade cladding.

• Glass laminated wire.

• Sunshade screen. • Wire mesh facades . • Shade

screens.

• Architecture ceilings.

6. Our Service

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: woven wire screen mesh architectural steel mesh |

|

Customizable Copper Wire Mesh for Elevator Cladding |

|

High Durability Guaranteed Copper Mesh Aluminum Frame Design |

|

Decorative Antique Plated Finish Metal Mesh Panel for Cabinet Door Insert |

|

Anti Corrosion 0.15 Opening Bronze Color Aluminum Metal Decorative Wire Mesh |

|

Support Pattern Design Decorative Wire Mesh for Cabinets Over thickness 0.105 INCH |

|

Customization Architectural Wire Mesh For Decorative Applications |