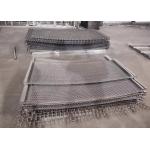

High Tensile 65mn Cement Vibrating Metal Woven Vibrating Screen

Mesh

Mining screen, also known as vibrating screen mesh, quarry screen, and crusher

screen, is one of the most

important and versatile parts of screening machines in the mining

industry, which separates a mix of particles into two or more

groups

depending on size and is widely used in a variety of sizing,

grading, scalping, dewatering, wet screening, and washing

applications.

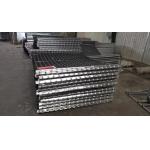

In its simplest form, the mining screen is a surface having many

apertures, or openings, usually with uniform dimensions. Particles

presented

to that surface will either pass through or be retained, according

to whether the particles are smaller or larger than the governing

dimensions

of the aperture. The efficiency of screening is determined by the

degree of perfection of separation of the material into size

fractions above

or below the aperture size.

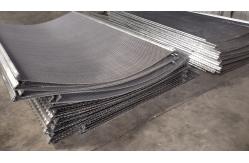

There are numerous different types of mining screens available. Our

products are fully customizable to fit most applications, including

capacity requirements. We adopt high-strength stainless steel to

provide high abrasion, corrosion and clogging resistance in the

harshest

conditions.

Our main materials are carbon steel and stainless steel wires, and

their parameters are listed as below.

Technical Parameters of Carbon Steel Wire| Grade | Chemical Composition(%) |

| C | Si | Mn |

| 45 | 0.42-0.50 |

0.52-0.60 |

0.50-0.80 |

| 50 | 0.47-0.55 |

| 55 | 0.52-0.60 |

| 60 | 0.57-0.65 |

| 65 | 0.62-0.70 |

| 70 | 0.67-0.75 |

| 65Mn | 0.62-0.70 | 0.90-1.20 |

| 72A | 0.15-0.75 | 0.15-0.75 | 0.30-0.60 |

| Grade | Chemical Composition(%) |

| C | Si | Mn | Cr |

| 304 | ≤0.08 | 8.0-10.5 | ≤2.0 | 18.0-20.0 |

| 321 | ≤0.08 | 9.0-12.0 | ≤2.0 | 17.0-19.0 |

| 316 | ≤0.08 | 10.0-14.0 | ≤2.0 | 16.0-18.0 |

| 2205 | ≤0.03 | 4.5-6.5 | ≤2.0 | 21.0-23.0 |

| 2207 | ≤0.03 | 6-8 | ≤1.2 | 24.0-26.0 |