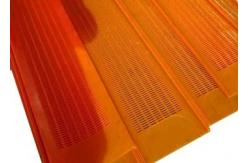

Fine Screening Flip Flop 30mm Thick Polyurethane Screen Panels Mat

|

|

Higher Wear Resistance Polyurethane Flip Flow Screen Media for Mining

Polyurethane Flip Flow Screen Normal Specification

Red Star High Performance Polyurethane Flip Flow Screen Media for Mining

Polyurethane Flip Flow Screen is mainly used for screening hard-to-screen materials, including sticky, fine and wet materials (such as highly sticky coal of high moisture content, and classification of medium & fine coke). The main advantages including high screening efficiency, long wearing life, wide application of particle size range, no pegging and no blinding. The flip flow screens are with high tensile strength, excellent wear performance, so as to achieve the designed service life of more than 4000 hours.

though having a lower opening screening area than wire screens, especially on smaller apertures, flip flow screens and mats, offer the advantage of a much longer lifespan and reduced noise levels. Manufactured from high wear resistant materials these screen mats are ideal as complete decks on larger screen boxes or as an impact section prior to a wire screen.

Polyurethane Flip Flow Screen1.Polyurethane Flip Flow Screen: square hole, long hole.

3.RedStar can also be customized to customer requirements of other sizes of Polyurethane Flip Flow Screen.

Polyurethane Flip Flow Screen Mode of Operation

The base frame is agitated by means of shaft and unbalance motor drive. The vibration is passed to the dynamic frame via thrust rubbers.Fixed screening mats between the dynamic and the base frame are clamped and fl exed by the two vibrating frames. The modular and compact construction of the Red star Flip-Flow-Screen ensures a wide acceptance for many different applications. The easy assembly respectively changing of the screening mats, the extension to a multi-deck version and the dynamic stroke adaptation are further features. The vibrating cover can be opened without tools. This ensures a rapid and easy accessibility of the screening mats. The relative movement of both screening frames creates a “trampoline effect” for the screening mats. The advantages of this effect are:

1.High acceleration up to 50g in the screening mats

2.Loosening-up of the product

Polyurethane Flip Flow Screen Features1, flip flow screens using the best quality raw materials production, product-specific high wear resistance. Long service life.

Polyurethane Flip Flow Screen Features Application

Polyurethane Flip Flow Screen is widely used for the classification of bulk material, such as

coal, minerals, coke, beans, etc. So it can be used in the

agriculture, chemical industry, minerals, quarry and smelting

industries.

Efficient screening of difficult, sticky or wet materials with separation cuts of 0.2 to approx. 50 mm.

Flip flop or flip flow screening machines have been in operation for decades for screening of moist or humid materials. Some typical applications Iron Ore at 6mm with 15% moisture · Raw sand at 3mm with 6% moisture · Compost at 10mm with 50% moisture · Slag at 3mm with 10% moisture · Salt at 3 mm with 5 % moisture · Coke at 3mm with 20% moisture · Lignite at 6mm with 50% moisture · Coal at 6mm with 18% moisture · Limestone at 3mm with 20% moisture · Pet coke at 3mm with 18% moisture · Plus other hard to screen materials like wood chips, bamboo chips, washery waste, building rubble, soil, plastic, auto parts etc. Principle of Operation : Generally referred to as “flip flow” or “ flip flop” screening method. During the cycling of screener, the flexible mats are individually tensioned and relaxed, which breaks or loosens the adhesive bond within the materials, and between the material and flip flow screen mats. In the upstroke, the material is impelled upward functioning like a trampoline and air is drawn in and through the material. The motion is such that the acceleration on machine support frame could be approx 3g whereas the material on the screen panels may experience around 50g. During these stretch & relax moments, the openings or aperture in the screen mats get elongated , stretched or bend which tremendously helps in release of particles which might have got jammed.

Flip Flop Polyurethane Screen Panels Mat Flip Flop Polyurethane Screen Panels Mat |

||||||||||||

| Product Tags: 30mm thick polyurethane screen panels hexagonal hole polyurethane screen panels 30mm thick pu screen | ||||||||||||

|

Quarry Rock Vibrating Screen Shaker Screen Sand Filter Mesh |

|

Wholesale Galvanized Square Woven Wire Mesh / Stainless Steel Crimped Wire Mesh |

|

High Tensile Strength 8x13mm Openning Stainless Steel Crimped Wire Mesh |

|

Rock Hooked 4mm Mining Screen Mesh Sgs Approved |

|

Color Painted 16mm Woven Wire Screen For Crusher |

|

0.7 - 20mm Gi Crimped Wire Mesh 45# Medium Carbon Steel |