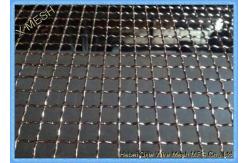

1.5X2m High Carbon Steel Square Hole Vibrating Screen Mesh

|

|

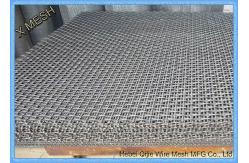

Stainless Steel Screen Mesh / Crusher Screen Mesh

Product Description Flat top woven wire screen material: Carbon steel wire; manganese steel wire; stainless steel wire.

Stainless Steel Material Parameter:

Stainless steel screen mesh weaving type: Double weaving, intermediate crimped, flat top and lock crimp, triple. Stainless steel screen mesh stock list in the download

Crusher Screen Mesh Weaving type:

Application: Material:

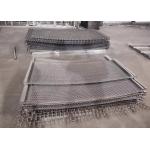

Lock vibrating screen Mesh Application:

Performance standard: ISO 14315 Industrial wire screens - Technical requirements and

testing

woven wire cloth

vibrating screen mesh

vibrating screen mesh-002

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: vibrating sieve screen vibrating screen wire mesh | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Wholesale Galvanized Square Woven Wire Mesh / Stainless Steel Crimped Wire Mesh |

|

High Tensile Strength 8x13mm Openning Stainless Steel Crimped Wire Mesh |

|

3/4" Opening Aluminum Alloy Woven Crimped Wire Mesh For Screen & Walls |

|

Quarry Rock Vibrating Screen Shaker Screen Sand Filter Mesh |

|

Rubber Self-Cleaning Vibrating Screen Mesh For Shale Screening |

|

High Tensile Woven Wire Screen Mesh 65mn 45# Manganese Steel Wire |