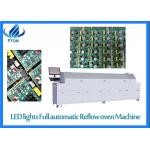

SMT Reflow oven with 8 temperature zone Welding with hot air 450mm (mesh)

|

|

SMT Reflow oven with 8 temperature zone Welding with hot air

Product description Reflow soldering oven is an important part of SMT. Generally speaking, the process of SMT is that PCB bare board is printed by solder paste printer, SMD components are placed on PCB board by SMT pick and place machine, and finally the reflow soldering oven uses the melting point of solder paste for permanent welding, which plays an important role in forming permanent solder joints between SMD components and PCB board.

Feature

Parameter

SMT line The general wiring sequence in SMT is solder paste printer, SMT Pick and place machine and reflow soldering oven. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Speed SMT And Reflow Oven Line High Stability SMD Reflow Oven For BGA Repair Best Selling |

|

Vacuum Reflow Soldering Ovens Smt Reflow Soldering Machine Automatic SMT Line |

|

ETON 12 Zones SMT Reflow Oven With Hot Air Heating System / Mesh Chain Transmission |

|

W-3000 SMT Reflow Oven With Flux Collecting System For Environmental Emission |

|

High-Precision Temperature Control SMT Reflow Oven Patented Air Management System |

|

LED Production Line SMT Reflow Oven With Intelligent Diagnosis System |