OD Mounted Industrial Pipe Cutting And Beveling Machine for Electric Driver

|

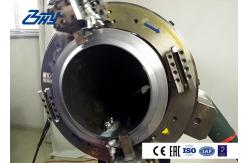

Industrial OD Mounted Pipe Cutting And Beveling Machine

Product Introduction |

| Model | A (mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | G(mm) |

| SFM0206 | 176 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM0408 | 228 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM0612 | 332 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM0814 | 364 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM1218 | 468 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM1420 | 518 | 70 | 122 | 176 | 225 | 253 | 164 |

| SFM1824 | 622 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM2026 | 674 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM2430 | 776 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM2632 | 826 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM3036 | 928 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM3238 | 1006 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM3642 | 1082 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM4248 | 1236 | 102 | 98 | 176 | 235 | 253 | 174 |

| SFM3648 | 1296 | 140 | 220 | 276 | 235 | 253 | 174 |

| SFM4860 | 1600 | 140 | 220 | 276 | 235 | 253 | 174 |

| SFM6072 | 1905 | 140 | 220 | 276 | 235 | 253 | 174 |

| SFM7284 | 2210 | 140 | 220 | 276 | 235 | 253 | 174 |

Manufacture

Working on site

■ Project: theramal power repaire

■ Pipe material: P91

■ Pripe O.D. : 1400mm

■ Pipe thickness: 110mm

|

2inch - 48inch Pipe Cutting and Beveling machine, cold cutting,2 to 48inches pipe cutting,2 to 48inches pipe beveling |

|

18in - 24in Pipe Cutting and Beveling Machine with electric motor |

|

6in - 12in Pipe Cutting Beveling Machine |

|

Split Frame cold pipe cutting and bevelling machine |

|

Stainless Steel 18in Pipe Cutting Machine, 30mm wall thickness, Cutting & Beveling |

|

Portable Electric Pipe Cutting Beveling Machine For Chemical Plant , Natural Gas |