Small Size Pneumatic Pipe Cutting And Beveling Machine Occupying

Small Space

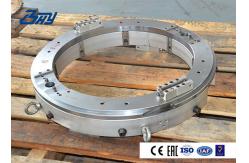

Split Frame Machine

Product Introduction

SFM series are portable processing equipment for cutting, beveling

and end prefabrication of various pipes, with which cutting and

beveling can be conducted at the same time. The SFM Series

manufactured by Bohyar cuts and bevels the pipe end or middle of

pipe by clamping external wall, with processing diameter up to 2100

mm and maximum wall thickness of 100 mm. With an R&D history of

nearly one hundred years, the product can process pipes or casings

accurately, continuously and vertically.

Specifications

We have three drive modes and they also have different technical

parameters. The air requirements are 2-3m³/min. The hydraulic

requirements are 65L/min, 10mpa. The electric requirements are

220V/AC. We adopt the star wheel system with 0.08mm/r feed amount.

The finish is anodizing sand blasting. We have different packaging

methods such as aluminum alloy, metal packing case or wooden box

according to the different models of split frame machines.

Our Advantages

■ Material

Fixed rings use lightweight and high-strength imported aeronautical

aluminum with anodized surface;

Moving coils use mold steel with chrome-plated surface .

■ Technology

Eccentric shafts and gear shafts used grinding process after

quenching to ensure the accuracy of the tooth surface.

■ Power

Three imported motors to choose from: Germany Metabo electric

motor, imported pneumatic motor and American White hydraulic motor.

On-site Service Reference

| Site location | Henan, China |

| Industry | Power Station |

| Pipe O.D | 56" (1414mm) |

| Wall thickness | 110mm |

| Bevel type | Double D |

| Material | 15Cr,P91 |

| Weld width | 80mm |

| Machine | SFM4860 |

| Other information | Cut and bevel the weld, but not cut off; Narrow working space. |

| Results | Finished the work successfully and got the commendatory letter from

our client. |

Report on Comparison of Product Advantages

| Name of component | Bohyar | Others | Advantages |

| Fixed coil | Imported aviation aluminum | Steel 45# | Light |

| Moving coil | Die steel | Steel 45# | Solid and durable |

| Tool | Imported tool material | Low price | Good quality |

| Tool slide | Die steel | Steel 45# | Solid and durable |

| Tool slide structure | Compact and small size | Large | Small size |

| Eccentric shaft | Quenching and grinding processing | Lathe processing | High precision |

| Gear | Gear-grinding processing | Gear-shaping processing | High precision, stable operation and low noises |

| Power supply (electric) | Germany motor | Low price | Strong power, stable operation, low noise and long service life |

| Power supply (pneumatic) | Taiwan pneumatic motor | Low price | Strong power, stable operation, low noise and long service life |

| Power supply (hydraulic) | White motor | Low price | Strong power, stable operation, low noise and long service life |