Weight Indicator Bagging Controller For 25KG Packing Weighing

Control

Software Function

1. Manual Screen-locking/Screen-unlocking, Auto Screen-locking,

Digital Setting&Calibration and I/O Testing functions

available.

2. Zero Upon Power Up, Zero Auto-tracking, Manual/Auto Zero and

Zero Calibration available.

3. Load Calibration and Loss Calibration functions available.

4. 100 Recipes for packing control.

5. Optional ‘Auto Correct Inflight’ function.

6. Optional ‘Pause for Tolerance Alarm’ and ‘Auto Dribble Re-feed’

functions.

7. Optional ‘Batch Target Control’ function [With Batch Count

Target or Batch Weight Target finished, the packing process will

stop automatically].

8. Optional ‘Flow Control’ function for Bucket Scale.

Outline Size [W×H×D]

7”: 226.5 × 163 × 36 mm.

10.2”: 274 × 193 × 40 mm.

Error Messages

| Message | Alarm Cause | Solution |

| RAM Fault | The chip RAM is damaged. | Replace the chip RAM. |

| EEPROM Fault | The chip EEPROM is damaged. | Replace the chip EEPROM. |

| Parameter Error | The chip EEPROM is damaged. | Replace the chip EEPROM. |

| Weighing Signal Error | Weighing signal reversed or not connected. | Connect the loadcell correctly. |

| ADC Fault | The chip ADC is damaged. | Replace the ADC module. |

| Over ADC Range | Weighing signal exceeds A/D conversion range. | 1. Check if the loadcell is connected.

2. Check if the capacity of loadcell is too small.

3. Check if the loading weight is too big. |

| Overload Alarm | Weight > (Scale Capacity + 9 × Scale Division). | 1. Check if the set value of parameter [102] ‘Scale Capacity’ is

reasonable.

2. Check if the loadcell is connected.

3. Check if the capacity of loadcell is too small.

4. Check if the loading weight is too big. |

| Internal Data-bus Fault | | Please contact manufacturer. |

Power Supply Terminal

| No. | Pin | Description |

| DC24V | DC24V[±20%] Power Input Port |

| 1 | - | DC Input -. |

| 2 | + | DC Input +. |

| For separating the controller from the interference of the driving

devices, the DC24V power supply of the controller should not be

shared by the DI/DO. |

Installation Mode

Size Option:

7 Inch One:

Outline Size [W×H×D]: 226.5 × 163 × 36 mm

Panel Cut-out Size [W×H]: 215 × 152 mm

10 Inch One:

Outline Size [W×H×D]: 274 × 193 × 40 mm

Panel Cut-out Size [W×H]: 261 × 180 mm

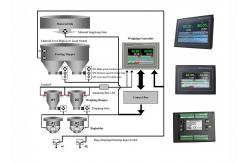

System Diagram For APP1.1 1-Bucket Scale

System Diagram For APP1.2 2-Bucket Scale[1-scale]

System Diagram For APP1.3 2-Bucket Scale[2-Bag]Mode

Delivery