Parallel Twin Screw Extruder Screw Elements W6mo5cr4V2 Materials

|

|

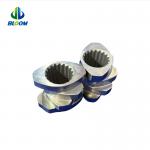

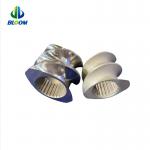

Parallel Twin Screw Extruder Screw Elements W6mo5cr4V2 Materials

1 . Factory introduction We are a professional manufacturer of nickel base alloy, Hastelloy alloy, tungsten carbide alloy, cobalt base alloy and H.I.P liner sleeve.

We have provided super wear-resistant high corrosion resistance bushing for many domestic and foreign parallel twin-screw extruder customers and modification enterprises, and can be developed according to customer needs, combined with the actual conditions of high quality non-standard products, Oze product performance is excellent, stable quality, reasonable price, timely delivery, perfect after-sales.

At present, the factory area of the company is over 3000 square meters, and another 3000 square meters are under planning and design, covering the complete production process of material research and development, main parts production and testing. The company has 6 technical personnel, more than 40 front-line workers, a number of Taiwan, Germany imported production and testing equipment. Currently there are two production plants in China.

2 . Properties of Nickel-Chromium-Tungsten Alloy Nickel-Chromium- Tungsten alloy has excellent abrasion resistance and corrosion resistance. The increase of Cr content in the nickel-chromium alloy matrix contributes to the oxidation resistance, high temperature resistance and corrosion resistance of the alloy. At the same time, the addition of CrB is better than WC. The microhardness of CrB is as high as 4000-4200DPH, which is close to diamond. It is more conducive to improving the overall strength of the alloy. Due to the high density of WC, it is about 15.7g/cm3, while the matrix of nickel-chromium alloy is only about 8g/cm3. The melting is caused by the uneven surface and depth of the alloy due to the easy segregation of WC, so the content and particle size of WC must be controlled. Nickel-Chromium-Tungsten alloy( we call WJ65) hard phase increased to about 50%, OS02 and OS25 only ten to thirty,Moreover, the fusion is not sufficient, and the microscopic pores are relatively obvious, which is reflected by the Rockwell hardness HRC of only 52-55 While the Rockwell hardness of nickel chromium tungsten alloy (WJ65) is HRC56-64, the conventional control is HRC58-60. The service life is 3-5 times longer then WR5 or CPM10V Nickel-Chromium-Tungsten alloy( WJ65 )on the basis of Ni60 in accordance with foreign twin screw working conditions of the formula, greatly improved Hard phase carbides (containing tungsten carbide chromium carbide and other carbides), and the nickel pool fullDissolve. Our Ni-Cr -W alloy layer can reach HRC64 is the best proof.

Chemical composition( %)

3 . Product details

Semi-finished Product

Finished Product

Recommendation Index: Main Materials : NiCrW alloy (Ni60 based on the addition of CrC and CrB Main Features: Wear resistance, corrosion resistance, belongs to the special alloy, hardness in HRC≥57, alloy parent full melt, improve the density, hardness. Structure Drawing:

New Process Of Spray Welding

The Main Process Is Different (from the original sintering process

to the current spray welding process) The product has better densification, the hardness can reach more

than 57 degrees, and the service life of the product is 3-5 times

that of the sintering process. Type 35, Type 40,type 50, type 65 with integral nickelchromium tungsten, 75 and above 75 can made by composite liner.

4 . Our QC Control Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

5 . Our detection Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

5 . Our Advantage 1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry: BLOOM(suzhou) Materials Co.,Ltd Email: sales1@ttxalloy.com

|

|||||||||||||||||||||

| Product Tags: Parallel Twin Screw Extruder Parts Twin Screw Extruder Screw Elements W6mo5cr4V2 Extruder Screw Elements |

|

High-efficiency mixing 30mm Bimetallic Screw And Barrel Set for Lithium Battery Slurry |

|

ZSK Twin Extruder Parts Screw Elements for Lithium Battery Slurry Production |

|

Custom Cobalt Alloy Screw Segments For Lithium Battery Slurry Production |

|

Extruder Repairing Parts Screw Segments To Lithium Battery Slurry Production |

|

Conical Twin Screw Barrel / Extruder Screw Barrel For Pipe Extrusion |

|

Extruded Screw And Barrel Screw Element Customized Segment For Twin Screw Extruder Machine |