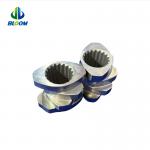

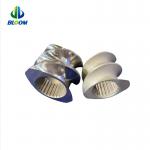

316L Twin Screw Element For Plastic Masterbatch Machine Production Line

|

|

Twin Screw Element For Plastic Masterbetch Machine Production Line 1. Descriptions

All component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-screw plastics machines. And check the extruder screw elements and metallography to ensure that the raw materials are e and nothing wrong.

100% internal spline is checked with a spline plug gauge to ensure the interchangeability of components.

All of our twin screw extruder elements are finished by CNC grinding after heat treatment. The surface roughness of this series is less than Ra0.8, which completely eliminates the influence of heat treatment deformation on the quality of components.

2 .Twin screw extruder screw element parameter:

3. Screw and barrel barrel screw extruder screw barrel processing: Raw material - brand - testing - machining - grinding process - antirust process - products - packing - delivery to your hand

4 . Pictures:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 26mm Center Distance Twin Screw Element Plastic Masterbetch Machine Twin Screw Element 316L Twin Screw Extruder Spare Parts |

|

High-efficiency mixing 30mm Bimetallic Screw And Barrel Set for Lithium Battery Slurry |

|

ZSK Twin Extruder Parts Screw Elements for Lithium Battery Slurry Production |

|

Custom Cobalt Alloy Screw Segments For Lithium Battery Slurry Production |

|

Extruder Repairing Parts Screw Segments To Lithium Battery Slurry Production |

|

Conical Twin Screw Barrel / Extruder Screw Barrel For Pipe Extrusion |

|

Extruded Screw And Barrel Screw Element Customized Segment For Twin Screw Extruder Machine |