Spot Welding Electrode Material , Light Pneumatic Tip Dresser Easy Handling

|

|

Pneumatic Tip Dresser For Spot Welding 1 . Description

The function of the electrodes is to conduct the current and to withstand the high pressures in order to maintain a uniform contact area and to ensure the continued proper relationship between selected current and pressure. Uniform contacting areas should therefore be maintained. Good weld quality is essential and depends, to a considerable degree, upon uniformity of the electrode contact surface. This surface tends to be deformed (mushroomed) with each weld. Primary causes for mushrooming are too soft electrode material, too high welding pressure, too small electrode contact surface, and most importantly, too high welding current. These conditions cause excessive heat build-up and softening of electrode tips. Welding of today´s coated materials also tends to contaminate the face of the electrodes.

2 . Features:

1. Small sized, light and easy to handle

3 . Type of cutter cases : The cutter case bore diameter acts as a guide so that the cutter dresses at the correct location relative to the tip. Please specify a cutter case that matches the tip size.4 . Size

4 . More pictures

|

||||||||||||||

| Product Tags: spot welding electrode tips material resistance welding electrode material |

|

Customized Welding Wrench Chrome Finish Metric Measurement 13D 16D Electrode Cap Remover |

|

Spot Welding Electrode Cap Tips Handheld Pneumatic Tip Dressing Tool |

|

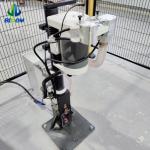

Electrical Electrode Tip Changer And Dresser For Spot Welding Robot Gun |

|

Automatic Electrode Tip Dresser Electrode Cap Changer and Dresser for Spot Welding Robot Gun |

|

Manual Operated Tool For Efficiently Changing Spot Welding Electrode Material |

|

Manual Operated Spot Welding Electrode Material Changing Tool For Efficiency |