High Output Fire Resistance Mgo Board Production Line Eco Friendly

|

Detailed Product Description

|

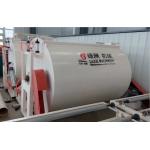

Automatic Fire-Resistance Magnesium Oxide Panel Production Line We have it with different automatic levels. The machine line

includes: automatic dosing system, forming machine, board receiving

machine, solidification, demoulding machine, cutting machine Raw materials are MgO powder, MgCl2, fiber glass, nonwoven fabric,

perlite, etc.

The MgO board is environmental friendly, high fireproof and waterproof, can be painted, laminated. nailed and sawn. It is widely used for ceiling, wall panel, decorating of indoor wall and lining board for furniture. MgO board can replace three-ply board, five-ply board, flakeboard, MDF (Medium Density Fiberboard ) and Gypsum Board. Product capacity 1.1200 pcs/8 hours (according to 10 mm thick wet board calculation) 2.1 million square meters per year (According to 10mm thick dry

board calculation) |

||||||

| Product Tags: High Output Mgo Board Production Line Eco Friendly Mgo Board Production Line Fire Resistance Mgo Board Production Line |

Related Products

|

Professional Magnesium Oxide Board Production Line Automatic Flying Saw |

|

Composite Partition MGO Board Making Machine With Single Shaft Mixer |

|

Composite Partition Wall Panel Mixer For Fiberglass MGO Board Machine |

|

Fireproof Wall Panel Single Shaft Mixer For MGO Board Making Machine |

|

PLC Control System Automatic Mixer / Blender For Fiberglass MGO Board Making Machine |

|

High Precision Mgo Board Production Line Automatic Mixing Tank With Agitator |

Email to this supplier