0.38mm Thickness Customised Pattern Laminated Colour Coated Aluminium Coil With Recyclable Material

|

|

Customised pattern laminated colour coated aluminium coil Customised pattern laminated colour coated aluminium coil offers versatile decorative solutions for architectural and design applications. This product features aluminium coils coated with durable finishes like PVDF or PE 3, then laminated with custom patterns such as wood grain, stone, marble, or artistic designs 13. Available in alloys including 1050, 3003, and 5052 with thicknesses from 0.1mm to 200mm 1, it combines aesthetic flexibility with functional durability. The lamination process enhances weather resistance and fade protection 7, making it ideal for exterior cladding, interior decoration, roofing, and signage. Customisable widths (up to 2,500mm 3) and colours enable tailored solutions for unique project requirements. Key advantages include:

Application About Prepainted Aluminum Coil Prepainted aluminum coil, which is produced with aluminum sheet or (aluminum coil) and processed by coating with color. In common sense, there are two kinds of prepainted aluminum coil-PVDF and PE, which are widely used in aluminum plate, aluminum veneer, aluminum honeycomb panels,aluminum ceiling, shingles, scrap, pop-top, electronics. PVDF coatings are known for their durability and weather resistance. They provide a smooth and glossy finish, making them suitable for architectural applications. PVDF coated aluminum coils are available in a wide range of colors and are often used for exterior cladding, roofing, and signage. PE coatings offer good UV resistance and color retention. They are commonly used for interior applications where extreme weather resistance is not required. PE coated aluminum coils are available in a variety of colors and are used for indoor decorations, ceiling panels, and more. Product Parameters

Product Advantages 1.High flatness: the surface is flat and smooth, without obvious

defects such as unevenness, wavy deformation, indentation or

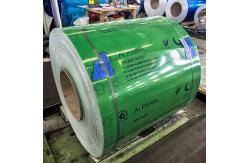

bulging. 2.Uniformity of colour: The colour is uniform and consistent, with no obvious colour difference. 3.Strong coating adhesion: good adhesion between the coating and the aluminium coil substrate makes it difficult for the coating to flake, peel or lose paint. 4.Good weather resistance: PVDF coatings have a colour stability of more than 20 years compared to 10-15 years for polyester coatings. 5.Strong corrosion resistance: The natural oxidation layer of aluminium combined with a protective coating such as PVDF ensures long term durability in harsh environments. 6.Malleability: complex bending and forming without cracking. Product Show

|

||||||||||||||||||||||||||||||||||

| Product Tags: Laminated Colour Coated Aluminium Coil 0.38mm Thickness Aluminium Coil Recyclable Laminated Aluminium Coil |

|

AA3003 H12 1.2MM Prepainted Aluminum Coil for Kitchen and Bathroom Supplies |

|

AA3003 H14 0.3 MM Color Pre-Painted Aluminum Coil for Billboards and Display Racks |

|

AA8011 O 0.03MM Pre-Painted Aluminum Coil for Food Packaging Industry |

|

Aluminum Alloy 8011 FreshSeal Foil (0.03mm/1500mm) for Fresh Milk Carton Packaging |

|

Aluminum Alloy 1060 SolarMirror (4.5mm/2000mm) for Concentrated Solar Power Reflector Substrate |

|

Aluminum Alloy 1050 (3.0mm/1800mm) for Anti-Glare Museum Display Case Panels |