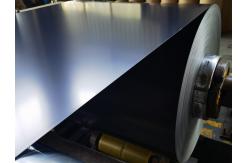

0.17mm Thickness Drainage Used With Pre-Painted Aluminium Sheets

|

|

Company Profile

Dingang/Senruida has been a professional manufacturer and experienced exporter of new material,focuses on R&D,manufacturing,processing high-end roller-coating aluminium coil material products since 2002.

Product Description of Color Coated Aluminum Sheet

Color coated aluminum sheets are aluminum sheets that have been coated with a layer of paint or a colored resin to provide them with a decorative finish and enhanced durability. The coating not only adds color but also serves as a protective layer against corrosion, weathering, and scratches. Color coated aluminum sheets are commonly used in various applications such as roofing, cladding, signage, and architectural decoration.

The Process of Color Coated Aluminum Sheet Involves Several Steps: 1.Surface Preparation: The aluminum sheet is cleaned and treated to ensure proper adhesion of the coating material. 2.Primer Application: A primer layer is applied to enhance adhesion between the aluminum substrate and the topcoat.

3.Color Coating: The desired color or resin is applied to the primed aluminum sheet using techniques such as roller coating, spray coating, or coil coating.

Product Parameters of Color Coated Aluminum Sheets

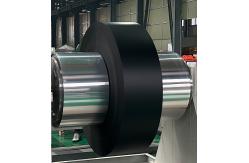

Our advantages of Color Coated Aluminum Sheets 1.Aesthetic appeal: They come in a wide range of colors and finishes, allowing for customization and aesthetic flexibility. 2.Durability: The coating provides protection against corrosion, UV radiation, and abrasion, extending the lifespan of the aluminum sheet. 3.Lightweight: Aluminum is naturally lightweight, making color coated aluminum sheets easy to handle and install. 4.Low maintenance: The coating helps to keep the surface clean and resistant to dirt buildup, reducing the need for frequent maintenance. Overall, color coated aluminum sheets are a versatile and durable solution for various architectural and decorative applications, offering both functional and aesthetic benefits.

Our certification:

Packaging & Shipping of Color Coated Aluminum Sheets The packaging and shipping of color coated aluminum sheets are crucial to ensure that the coils arrive at their destination in good condition and are ready for use.Proper packaging and shipping practices help maintain the quality of prepainted aluminum coils and ensure that they reach their destination in optimal condition.

Why Choose us ?

1.We are The Professional Manufacturer For Coated Aluminum Coil and Sheet . Choose us , you can save a lot us time from the trader business, We get your offer and produce the order as your request directly. and we are the professional in this industry , it is easy to understand what you want to get, Let us know what products you are produce for ,then we can according to your requirements recommend the material for you.

2.We Dipped In The Coated Aluminum Industry More Than 30 Years. From 1992, We started from a school subsidiary house for printing the paper. Then we went up year by year. We went through the Asian financial crisis in 1997, the global financial crisis in 2008,then became more and more stronger, in order to save energy for our company, Our market from developed countries such as U.S., U.K. to South-east countries, then back to Europe and Domestic market. We have owned more and more clients feedback due to the well reputation from the crisis.

3.We Export The Coated Aluminum Products More than 100 Countries worldwide. It is the most important that we are well known the requirement from different countries with different standards. From American stand to Europe Standard, We can easy to identify and strictly according to it. Also we are well know the different rule from different countries such as American clients well need the thickness in plus tolarance,but it should be minus tolarance thickness in south-east asia and Africa area.

4.We Never use the Re-Cycle Alumiunm Material. All of us know that aluminm are the re-cycle alloy that can save energy for our earth. but most of the color coated aluminum products are used in very strict and inclement weather district. The re-cycle aluminum can not staisfy the requirement of it . That's why we can continue our business for more than 30 years here and this is the reason why more and more clients choose us with our coated aluminum products.

5.Full Quality Test Room We Have In Our Company Before the Order Loading Out. Here in our company we have a full set of machines that can test any items of the coated aluminum quality such as coating thickness, Analysis of the Coating Content, The Aluminum Alloy Components, Temper, Tensile, Hardness,Etc., All the material that ship out to any countries should be test all the items during the production.

6.Worldwide serve systems. We have the 24 hours business service and we can solve any problem from North America to South Africa in one-day-time.

|

||||||||||||||||||||||||||||||

| Product Tags: color coated aluminum sheet aluminium colour coated sheet |

|

Alloy 3003 H26 Temper 0.45mm Thickness Ral Color Coated Aluminum Sheets For Building Exterior Panel |

|

3105 H24 0.8mm Color Coated Aluminum Sheet – Lightweight for Transportation |

|

Alloy 3003 H26 Temper 0.55mm Thickness Ral Color Coated Aluminum Sheets For Building Exterior Panel |

|

Alloy 3105 H34 Temper 0.43mm Thickness Ral Color Coated Aluminum Sheets For Building Exterior Panel |

|

AA3004 H24 1.0MM Color Coated Aluminum For Production Ceiling Panel |

|

AA5052 H18 0.3mm Coated Aluminum Coil For Precise Electronic Component Welding Needs |