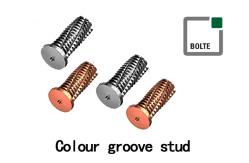

Colour Groove Stud, Welding Studs for Capacitor Discharge Stud Welding

|

|

BTH BOLTE Welding Studs for Capacitor Discharge Stud Welding

Colour Groove Stud

Colour groove stud

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip. This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.

Colour groove stud

Materials

Our welding studs are standardly made from the following materials:

The materia lspecifications conform with DIN EN ISO 13918 and DIN EN ISO 14555.Forwelding studs from other materials please send us you rinquiry or contact us. On demand, the material properties can be verified by an inspection document (test report,inspection certificate) according to DIN EN 10204.We are pleased to inform you about weldability to different base materials and welding parameters.

Welding studs dimensions are given in the measurement tables (all dimensions in mm).All standardised welding studs conform to DIN EN ISO 13918. Not standardised welding studs are supplied according to DIN EN ISO 13918. Special welding elements, which are not described, are delivered upon request. Dimensions that are not listed in the measurement tables are delivered upon request.

Welding studs for capacitor discharge stud welding have a cold formed calibrated welding pip with length and diameter tolerances closely controlled. At the welding pip the welding process is initiated and it determines the length of the welding time.Therefore exact dimensions of the welding pip are decisive for proper welding results.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: stainless weld studs aluminium weld studs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Steel Aluminium Capacitor Discharge Studs High Precision M10 Weldable Threaded Studs |

|

Aluminium Capacitor Discharge Studs Welding Machine Stud Flange Type |

|

Flange Type Steel Welding Studs For Capacitor Discharge Welding |

|

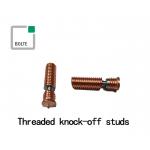

BTH BOLTE Welding Studs for Capacitor Discharge Stud Welding Threaded Knock-Off Studs |

|

Welding Studs for Capacitor Discharge Stud Welding Earth Plug Double Warth Plug |

|

Welding Studs for Capacitor Discharge Stud Welding Fir Tree Stud |