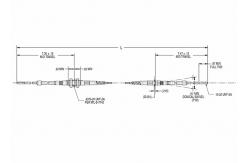

Push Pull Control Cable Assembly Simple Install Easy Maintain For Mechanical Starter

|

Detailed Product Description

Phidix High-Performance Push-Pull Control Cable – Built for Demanding Motion SystemsWhen failure is not an option, Phidix delivers.Designed for aerospace, defense, motorsport, and high-speed marine applications, our high-performance push-pull control cable combines precision, durability, and thermal stability in one compact assembly. This is not an off-the-shelf industrial product — it's a motion-critical solution engineered for mission-grade reliability. Key Features at a Glance• Extended Temp Range: From -65°F to +230°F, ideal for extreme operating environments. • Low-Friction Design: PTFE-lined conduit and smooth cable interface for minimal control

effort. • Durable Armor: Stainless steel core, heavy-duty conduit, and weather-resistant

jacket. • Tight Bend Radius: Supports confined installations without sacrificing performance. • Custom Stroke Lengths & End Fittings: Tailored to your control geometry. Why Choose the Phidix High-Performance Series?1. Thermal & Mechanical Stability That Outperforms Industrial

Grade While standard industrial-grade push-pull cables may suffice for

general machinery, they fall short under intense heat, vibration,

or tight integration layouts. This cable uses: • Aerospace-rated conduit layers for insulation stability. • Precision-ground wire core with enhanced tensile integrity. • Multi-layer PTFE liner to resist deformation under

continuous motion. By contrast, typical industrial units rely on PVC sheathing and

basic steel wire cores, which degrade or kink under thermal and

mechanical stress. Application Proven: From Cockpit to RudderThis cable has been deployed across: • Aircraft throttle and flap systems • Jetboat reverse gate controls • Racing vehicle brake/shift mechanisms • UAV payload actuation Whether your control system needs to perform flawlessly at 30,000

ft or on high-speed watercraft, Phidix delivers pinpoint accuracy

and reliability. Construction Overview• Inner Wire Core: 1×19 stainless steel (304/316L), compacted

for tensile load and compression strength. • Liner: Double-layer PTFE for consistent low-friction

motion. • Armor Braid: Galvanized or stainless steel, depending on

environment. • Outer Jacket: Flame-retardant HDPE, black or gray. • End Fittings: Threaded stud, clevis, swivel, or

customer-specified interfaces. Engineered to Fit – Not Just to FunctionMany industrial push-pull cables are "cut-to-length" models. Ours is designed-to-fit, where stroke, bend, tension, and

environmental constraints are all considered in the engineering

phase. This eliminates: • Excess cable slack • Abrasive friction points • Over-engineering cost Compared to Our Industrial Series

Custom Fit, Standard BackboneWhile this cable meets many common aerospace form factors, it remains fully customizable — stroke length, casing size, thread type,connector materials,all can be adapted to meet customer needs. We support the full process cooperation of OEM projects from design to sampling. |

||||||||||||||||||

| Product Tags: control cable parts push pull cable assemblies |

Related Products

|

Black Push-Pull Cable Assembly with Durable Stainless Steel or Carbon Steel Material |

|

Bulkhead Mount Control Cable Assembly Marine Push Pull Cable Boat Steering Cable |

|

Flexibility Mechanical Control Cable Push Pull Control Cable Automotive Control Cable |

|

Gear Shifter Control Cable Universal Shift Cable Assembly |

|

Transmission Control Cable Gearshift Control Cable |

|

Push-Pull Control Cable Push Pull Heavy Duty Universal Control Cable Assembly |

Email to this supplier