400 um Core/430um Fiber with hard plastic cladding ( Easy chemical

removal)

Fiberglass, or “glass fiber,” itself has a familiar base

structure and a wide variety of uses.

Fiberglass really is made of glass similar to that in windows or kitchen drinking glasses. To

manufacture fiberglass, glass is heated until molten,

then forced through superfine holes. This creates glass filaments

that are extremely thin—so thin, in fact, that they're best

measured in microns.

The glass would have to have a clear core surrounded by a

skin—called cladding,

and also made of glass—so that the cladding could reflect laser

light back into the core and keep it traveling along its path.

These flexible filament threads can be used in several

applications:

They can be woven into larger swatches of material or left in a

somewhat less structured form used for the more familiar puffy

texture used for insulation or soundproofing. The final application

is dependent on the length of the extruded strands (longer or

shorter) and the quality of the fiberglass.

For some applications, it's important that the glass fibers have

fewer impurities, however, this involves additional steps in the

manufacturing process.

The purity of the glass is maintained by using corrosion-resistant

plastic in the gas delivery system (valve blocks, pipes, seals) and

by precisely controlling the flow and composition of the mixture.

The process of making the preform blank is highly automated and

takes several hours. After the preform blank cools, it is tested for quality control

(index of refraction).

Specification :

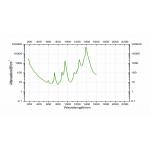

| Item | Wavelength

Range | Hydroxyl

Content | Core

Diameter | Cladding

Diameter | Coating

Diameter | Core /

Cladding | Coating | Proof Test | Stripping

Tool |

| HCW050UGA | 250 - 1200 nm | High-OH | 50 μm ± 2% | 125 ± 1 μm | 250 μm ± 4% | Pure Silica /

Fluorine-Doped Silica | Acrylate | ≥100 kpsi | T08S13 |

| HCW050LGA | 400 - 2400 nm | Low-OH |

| HCW105UCA | 250 - 1200 nm | High-OH | 105 μm ± 2% | 125 ± 1 μm | 250 μm ± 4% | T08S13 |

| HCW105LCA | 400 - 2400 nm | Low-OH |

| HCW200UEA | 250 - 1200 nm | High-OH | 200 μm ± 2% | 220 ± 2 μm | 320 μm ± 5% | T10S13 |

| HCW200LEA | 400 - 2400 nm | Low-OH |