BS476-20 Fire Resistance Construction Material Testing Equipment

|

Detailed Product Description

|

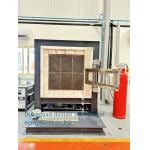

Construction Materials and Structures Flammability Resistance Test

Equipment for BS 476 Application: The test furnace refers to BS476 part 20 and 22

(vertical/horizontal ), GB9978-2008 standard, is to assess the

behavior of a specimen of an element of building construction when

subjected to defined heating and pressure conditions. The method

provides a means of quantifying the ability of an element to

withstand exposure to high temperatures, by setting criteria by

which the loadbearing capacity, the fire containment (integrity)

and the thermal transmittance (insulation) functions can be

adjudged. A representative sample of the elements is exposed to a laboratory

test for the determination of fire resistance of elements of

construction. Standard: BS476-20: Fire Tests on Building materials and structures – Part

20. Method of test for determination of the fire resistance of

elements of construction (General principles) BS476-22: Fire tests on building materials and structures-Part 22:

Method for determination of the fire resistance of non-loadbearing

elements of construction Test Function: The sample exposed to high temperature and pressure conditions, the

test samples within the specified time bearing weight, integrity

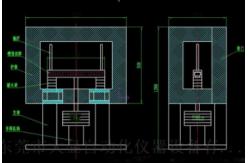

and insulation. Technical Parameters: 1. Test Furnace: ⑴ Test Furnace structure and size: Vertical furnace 3.1*3.1*1.2m(W*H*D), biggest sample size

3*2.8m(W*H) Comply with EN1363-1 The test furnace is made of brick, steel structure and fireproof

insulation material. 2. Voltage Supply: AC 380V ±10%, 50Hz 3. Power: The test furnace comply with ISO9705, output power is 300KW. 4. Burner system:

5. Test temperature control: ⑴ furnace temperature control meets the require of T-T0=345lg(8t+1) Temperature control deviation: 0min<t≤10min:d≤15% 10min<t≤30min:d≤10% t>30min:d≤5% ⑵ testing device accuracy: Furnace temperature: ±15℃ Sample inside temperature: ±10℃ Sample backfire temperature: ±4℃ ⑶ Timing range: 0-300 minutes, accuracy: <±1s 6. Furnace pressure meets (1) Test after 5 minutes, the furnace shall meet the following

positive pressure conditions: Components - in the furnace 3m heights, 100mm from the surface of

the specimen, furnace pressure 15Pa ± 5Pa; (2) Test after 10 minutes, the furnace shall meet the following

positive pressure conditions: Components - 3m in the furnace height, 100mm from the surface of

the specimen, furnace pressure 17Pa ± 3Pa. (3) The sample of the landing door can be kept at a constant

pressure over the whole height by the fire surface, the pressure

value at the ridge should be kept within 2 ± 2Pa, and the pressure

gradient inside the furnace should be 8 Pa per meter; (4) furnace pressure measurement range: 0-100Pa, measurement

accuracy: ≤ ± 3Pa 7. Temperature sensor The performance, quantity and location of the thermocouple in the

heating furnace meet the requirements of EN16341-1; a) Furnace temperature ± 15 ℃, adopts diameter 1mm thermocouple; b) The specimen backfire surface temperature ± 4 ℃, diameter 0.5mm

thermocouple. Copper plate with thermocouple: diameter 120mm,

thickness 0.50mm; c) Armored Platinum Rhodium Platinum S-value thermocouple accuracy

class: II level d) Armored nickel-chromium-nickel-silicon K thermocouple accuracy

class: II level Gas and air systems 1. Gas and vaporization equipment (1) Combustion gas source: propane and liquefied gas, 200KG / H

electronically controlled gasification gasified furnace, 8-10

bottles, 4-5 is used, 4-5 is standby, which are equipped with

automatic gas switching valve. (2) The DN48 seamless steel pipe for gas supply pipe should be

equipped with corresponding pressure reducing valve, safety valve

and so on. (3). Configuration of gas-saving device, equipped with flammable

gas leakage alarm device. Note: Laboratory gas to build a gas station room, size of about

L5000 × W4000 × H2300. 2. Air source system (1) Using high-pressure centrifugal fan + inverter to regulate flow

and pressure; (2) Configure appropriate switching valve, gate valve and pressure

gauge and DN75 seamless steel pipe. |

||||||||

| Product Tags: horizontal flammability tester vertical flame test chamber |

Related Products

|

DX8810A Steel Structure Fireproof Coating Sample Test Furnace |

|

Plastic, Glass, Fiber, Foam, Thermal Testing Equipment Insulation Materials Thermal Insulation Efficiency Tester |

|

BS476-7 Building Materials Lab Test Equipment Surface Flame Spread Test Apparatus Flammability Machine |

|

AstmeE84 Steiner Tunnel Testing Machine Fire Test Lab Testing Equipment UL910 |

|

UL1685 Wire & Cable Burning Test Device DX8297 |

|

UL790 Roofing Material, Fire Resistance Performance, Flame Retardant Performance Tester For Photovoltaic Cells |

Email to this supplier