Dimensional units:mm (Dimensions without tolerance are approximate

values)

Combustion device:

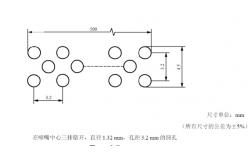

1. Spray lamp: a ribbon propane gas spray lamp with a nominal

length of 500mm and a width of 15mm, equipped with a Venturi mixer.

There are three rows of nozzles with a nominal diameter of 1.32mm

and a center distance of 3.2mm drilled holes.

2. Flow meter: Air flow meter: 80L/min; Propane flow meter: 5L/min

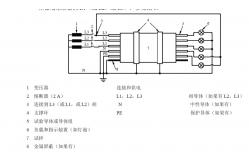

3. The composition of the spray lamp control system includes:

pressure regulating valve, piezoelectric igniter, extinguishing

device, temperature control thermocouple, gas source (provided by

your company), regulating valve, ignition device, gas pipeline,

flow meter, Venturi mixer, spray lamp, ball valve, air pipeline,

compressed air cylinder (user self-provided )

4. Timer: 0~99.99s/m/h, can be set arbitrarily

5. Ignition device: for automatic ignition

6. Temperature controller: composed of two temperature monitoring

parts, with a temperature range of 0~1000 ℃ and can be set

arbitrarily.

Including load: the test voltage is adjustable from 0 to 1000V;

Current range: 0.1-3A, the test current can be adjusted according

to standard requirements, but if it is greater than 3A, it will be

protected;

The load capacity should ensure that the test sample can continue

to be tested even when the test current approaches 3A.

The electrical circuit has appropriate protective devices to ensure

that during combustion or cable breakdown, personnel will not be

electrocuted and equipment will not malfunction due to cable

breakdown.

During the electrical circuit integrity test of the cable to be

tested during combustion, each circuit (three-phase) and neutral

point must be connected in series with a fuse to protect the

step-up transformer. When the safety wire fused disconnect, there

must be an indicator light to display the melting or grounding

phase.

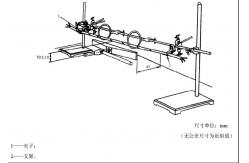

For the convenience of operation, when calibrating the temperature,

the fixed position of the specimen deviates from the ignition

source. After calibrating the ignition source, manually move the

specimen to the ignition source position.

If a touch screen is selected, it has the following functions:

automatically detect the temperature of two thermocouples, display

the temperature curve through the touch screen, and prompt an alarm

when the standard set temperature upper and lower limits are

exceeded (display curve time range of 15 minutes, digital display

does not have this function).

Compliant with standard: manufactured and produced according to the national standard

GB/T19216.11-2003 IEC60331-11.

Scope of application: Used to test the ability of wires and cables to operate

continuously under specified conditions under a certain fire source

and time. The testing instrument consists of an integrated design

of the testing and control parts. The outer shell and important

components of the testing chamber are made of stainless steel and

are resistant to smoke and gas corrosion. The control system has a

high degree of automation, with automatic ignition, touch screen

display, convenient observation and recording, and stable and

reliable use.

Gas source for testing flames: Using propane gas or liquefied

petroleum gas with a purity of over 95% (user provided ).

The burner is a belt type propane gas nozzle with a Venturi mixer,

with a nozzle length of 500mm and a width of 15mm. There are three

rows of staggered small holes on the nozzle, with a diameter of

1.32mm and a spacing of 3.2mm.

The nozzle should be at least 200mm away from the bottom of the box

and at least 300mm away from any box wall. (Box to be equipped

separately)

The inner diameter of the metal ring is approximately 150 mm.

Equipped with dual flow meters and pressure regulation, with an air

flow meter range of 0.5-5 cubic meters per hour and a gas flow rate

range of 0.1-1 cubic meters per hour. Equipped with a temperature

measurement device (K-type thermocouple), under the condition of

(750+50 ℃, -0 ℃), burn for 10 minutes, and the temperature

difference between the two thermocouples shall not exceed 40 ℃. The

test process is automatically controlled.

Equipped with intelligent detection function, it automatically

alarms and turns off the fire source when a short circuit occurs in

the sample during the testing process.

Provide 5 metal rings with an inner diameter of approximately 150

mm as required by the standard, and the distance between the metal

rings can be freely adjusted to facilitate the fixation and support

of the test piece.

Stainless steel sample holder, with a load-bearing capacity of

30kg.

Excluding combustion chamber (combustion chamber requires 27 cubic

meters), customer provided air compressor (3HP)