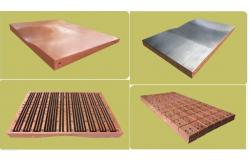

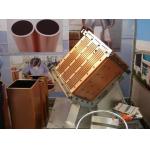

copper mould cystallizer applying for High speed thin plate DUE caster

|

|

Copper mould plate slab Continuous casting machine plate CCM wider plate

Situated in a critical position of continuous casting machine, copper mould requires extreme high thermal-conductivity and high strength. The molten steel will be formed into a certain shaped steel billets immediately after it passes through the copper mould.

Besides basic function of shaping and solidifying the steel strand, copper mould is of great influence on the economics of continuous casting lines.

Not only the cost, the service life of copper mould and the quality of the cast product are also considered as important factors by the users.

Therefore, suitable mould design as well as study of continuous casters and working conditions is making stringent demands on the manufacturers.

BEIJING SINO STEEL Mould Factory is one of the leading manufacturers of the copper mould in China. With more than twenty years experience and through adopting advanced German technology, BEIJING SINO STEEL copper mould has been winning acceptance from the users worldwide.

Our specialized know-how, quality control and service enable us to satisfy the market’s changing requirements. Concentrating on adaptability to the improvement of continuous casting technology with continuously ongoing research and development word, BEIJING SINO STEEL is providing optimal solutions to your moulds.

Product Scope:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: patterned copper sheet carbon steel plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ESP CSP DUE Copper mould plate CuAg Cu-Cr-Zr copper silver Nickel coating |

|

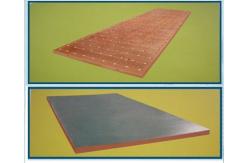

CuAg with coating, CuCrZr with coating,Copper mould plate for CSP, ESP, QSP caster |

|

Chrome Coating Copper Sheet Plate , Low Carbon 1 Mm Thick Copper Sheet For Casting Machine |

|

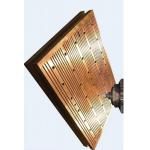

Longer Funels Copper Mould Plate and wide Type Shorter Funel With Good Thermal Performance |

|

Wear Resistance Copper Mould Plate For Continuous Casting Machine with ISO Certification |

|

Narrow Wider Sizes Copper Mould Plate and Square Structural With Long Or Short Funel type |