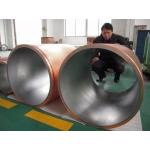

Copper mould tube for CCM Cr-plating NiCr-coating NiFe-plating

Situated in a critical position of continuous casting machine,

copper mould requires extreme high thermal-conductivity and high

strength. The molten steel will be formed into a certain shaped

steel billets immediately after it passes through the copper mould.

Besides basic function of shaping and solidifying the steel strand,

copper mould is of great influence on the economics of continuous

casting lines.

Not only the cost, the service life of copper mould and the quality

of the cast product are also considered as important factors by the

users.

Therefore, suitable mould design as well as study of continuous

casters and working conditions is making stringent demands on the

manufacturers. Round Mould | No. | Length (mm) | Section Dimension (mm) | Curved Radius (mm) | Wall Thickness (mm) | Cr-Coating Thickness (mm) | | 1 | 780 | Ф156 | 9000 | 14 | 0.10 | | 2 | 780 | Ф178 | 9000 | 14 | 0.10 | | 3 | 850 | Ф300 | 9000 | 14 | 0.10 | | 4 | 1000 | Ф500 | 9000 | 14 | 0.10 | | 5 | 1000 | Ф800 | 9000 | 14 | 0.10 |

Material | Material | Chemical Composition | Mechanical Properties | Electric Conductivity (%IACS) | Cu

(%) | Others

(%) | Tensile Strength σ b (N/mm2) | Yield Strength σ 0.2 (N/mm2) | Elongation

δ

(%) | Hardness (HB) | | E-Cu | >99.90 | | 200 | 40 | 40 | 45 | 98 | | SF-Cu | >99.85 | P0.015-0.040 | 240-310 | 190-250 | 25-10 | 80-95 | 85 | | CuAg | >99.50 | Ag0.08-0.12 | 240-310 | 200-225 | 16-10 | 110-125 | 95 | | Cu-Cr-Zr | >98.0 | Cr0.3-1.2

Zr0.08-0.3 | 375-445 | 280-355 | 20-13 | 115-130 | 80 |

Product Scope:

| Material | E-Cu, SF-Cu (DHP Cu), CuAg, Cu-Cr-Zr | | Design | Square, rectangular, round , plate, H beam | | Straight or curved | | Outer contour parallel | | Internal geometries: parallel, single tapered, double tapered,

multi-tapered, parabolic tapered, convex tapered | | Size | Square: □ 80mm~500mm

Arc Radius: 4000-17000mm

Wall thickness:6-50mm

Length: 700-1000mm

Rectangular: 100-500mm×650mm

Arc Radius: 4000-17000mm

Wall thickness:6-50mm

Length: 700-1000mm

Round: Ф110-Ф1200mm

Arc Radius: 5000-17000mm

Wall thickness:10-50mm

Length: 700-1000mm

H-beam: Intergrated stype

Arc Radius: 6000-17000mm

Wall thickness:12-50mm

Length: 780-1016mm

| | Coating | Coating material: Cr, Ni-Cr, Ni-Fe or Ni-co |

| 21 | 1000 | □135×135 | 6000 | 10 | 20 | 10 | 0.06~0.08 | | 22 | 810 | □135×135 | 5250 | 12.3 | 18.3 | 6 | 0.07~0.09 | | 23 | 780 | □140×140 | 7000 | 11 | 16 | 6 | 0.06~0.08 | | 24 | 801 | □140×140 | 10250 | 12 | 18 | 6 | 0.06~0.08 | | 25 | 812 | □140×140 | 8000 | 12.3 | 20 | 8 | 0.10 | | 26 | 835 | □140×140 | 7924.8 | 12.5 | 17 | 6 | 0.10~0.12 | | 27 | 800 | □143×143 | straight | 11 | 21 | 10 | 0.06~0.08 | | 28 | 700 | □150×150 | 9000 | 12 | 20 | 8 | 0.08~0.10 | | 29 | 780 | □150×150 | 6000 | 12.5 | 18 | 5 | 0.08~0.10 | | 30 | 780 | □150×150 | straight | 10 | 22 | 12 | 0.06~0.08 | | 31 | 800 | □150×150 | 5250 | 12 | 20 | 8 | 0.08~0.10 | | 32 | 810 | □150×150 | 6000 | 12 | 22 | 10 | 0.06~0.08 | | 33 | 812 | □150×150 | 5250 | 15 | 27 | 12 | 0.06~0.08 | | 34 | 812 | □150×150 | 8000 | 12 | 18 | 6 | 0.13 | | 35 | 850 | □150×150 | 6000 | 12 | 20 | 8 | 0.06~0.08 |

|