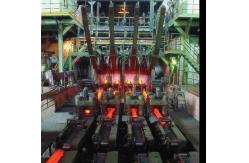

Rotary Arm Aluminium Continuous Casting Machine and Brass Continuous Casting Machine

|

|

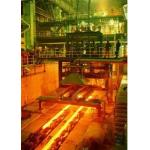

CCM Continuous Casting Machine Ladle turret Rotary arm dummy bar

Steel billet continuous casting machine

A. Advanced technology in the continuous caster Based on the strong technical force and many leading experts absorb new technology and new process from the world, and practical experience of every user. Low manufacturing cost, It is easy to maintenance.

Parts introduction

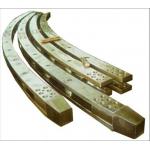

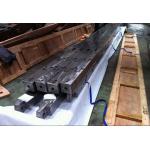

1. Energy-saving withdrawing and straightening machine Energy-saving withdrawing and straightening machine is a key parts of continuous casting machine which is used insert the dummy bar into mould and withdraw strand from mould and straighten it with dummy bar. Range of Radius: 3-14m

2. High-efficiency mould

Water jacket:4-8mm

Copper tube length (mm): 812 850 900 1000

3. Ladle turret:

Function

Ladle turret plays the role of move the molten steel from ladle to pouring position. It consist of Rotary arm, rotary bearing, transmission device

Load Compacity: 50-200 ton. Angle of rotation: 360 degree Rotating speed: 1 rotation/min. Swing motor capacity: 7.5-15kw

B. Parameters

|

||||||||||||||||||||||

| Product Tags: upward continuous casting machine aluminium continuous casting machine |

|

High Efficiency CCM Continuous Casting Machine With Different Billets Section Size |

|

Various Carbon Steel Continuous Casting Machine Easy Operation And Installation |

|

One and Multi Strand CCM Continuous Casting Machine Upward For steel Casting |

|

Vertical and curved Types Steel Billet CCM and Copper Continuos caster |

|

High Withdrawal Speed Copper CCM Continuous Casting Machine and Steel Casting Machine |

|

slab billet square type hot metal CCM Continuous Casting Machine |