Compact Digital Screen Printing Machine , Automatic Silk Screen Press Ceramic / Glass Transfer Film

|

|

Allfine Group-20 years experience Solution 1: Save material 2: Improve efficiency 3:Professional tranning 4: Factory built Partner Manager-Jack Huang

1050AG Full Automatic Stop Cylinder silk Screen Press ceramic and glass transfer film,advertising,packing printing ect screen printing production line.pdf We provide the classic automatic stop-cylinder screen press with

max. speed up to 4,000 sheets/hour, which can compete with world

famous brand like Sakurai and SPS. And the semi-automatic and 3/4

automatic flat-bed screen press are also available for short run

jobs. You can also find all necessary auxilaury machines for making

the screen plate in our product range.

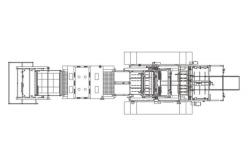

Feeding part: Full automatic non-stop feeder with pre-stacker,

non-stop primary and secondary feeding program, saving the working

time, easy to operate , increase the efficiency, raised feeder

height ensure the feeding height. Feeder: Efficient and stable compact feeder head design, with two

suck two delivery four suction, Adsorb and delivery different

thickness paper stably. Note: it can be equipped with the

anti-static device for substrates with high static content. Feed board: Feed surface is worked by plating, avoid the rear of

printing substrates to be scratched, at the same time feeding is

very smooth; with the sensitive sensor it will stop automatically

if without paper. Cylinder and register system: Cylinder stops step automatically to

ensure the forehead of the printing stock can be sent accurately to

the gripper of cylinder , which is up to extreme high precision; at

the same time, gripper of cylinder and pull side-lay both have

there magic eyes for supervising if the printing stock is in

correct place. Squeegee system: Two cams separately control the movement of

squeegee and ink return blade; squeegee with the pneumatically

pressure kept device, the printing graphics is more clearly and the

ink layer is more well-proportioned. The screen frame rack can be pulled out, which is easy for

adjusting the register or feeding, as well as cleaning the cylinder

and screen frame; at the same time, it is assembled with device to

hold the ink dropped to avoid the ink drops on the cylinder. Delivery board: can be turned down by 90°, easy to adjust the

screen frame, fix blade, clean and inspect; with vacuum adsorption

ensures delivery smoothly. The two wider convey belt which can

avoid the belt break the substrate. Cover lift system: The inside temperature is inspected

multipointly, if the temperature is abnormal the machine will stop

automatically, as well as the cover will lift automatically. Youtube link of LC-1050AG full automatic screen printing machine: http://youtu.be/txKHMVQx5Ew For more information, please add my

whatapp/viber/mobile/wechat/qq:+8615158408090 There will be an operation training for operator: (1) Training for right operation; (4) Introducing after-sale services and notify the contact way; Accessories supply guarantee: We supply free accessories within one year warranty period. We will charge you for accessories supply when the warranty is overdue; |

||||||||||||||||||||||||

| Product Tags: automatic screen printing machine automatic screen printing press |

|

High Speed Inspection And Slitting Line Paper , Adhesive Label , PVC , PE And PP |

|

Paper And Film Slitting Machine 400mpm Tipping Paper Packet Of Cigarettes |

|

200mpm Horizontal Roll Slitting Machine BOPP PET CPP PVC Aluminum Foil And Paper |

|

350MPM Shaftless Unwinding Thermal Paper Slitting Machine PLC Mitsubishi Delta Inverter |

|

Full Rotary Semi Intermittent Die Cutting Machine With Slitting 1 Color Print Sheet Cutting Collection Table |

|

Rotary Blank Label Die Cuting Machine With Slitter With One Set Magnetic Cylinder And Magnetic Die |