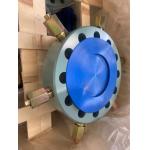

Single / Double Or Triple Sealing Stuffing Box For Oilfield Cementing

|

|

Stuffing Box Detail information The API 11B Oilfield Polished Rod Sealing Box, commonly known as a stuffing box, is a crucial component installed at the Pumping Well Head. Its main purpose is to seal the Polished Rod using cone packing and a lubricated upper section. This design ensures self-alignment, prevents packing burnout, and effectively seals against fluid pressure leakage. The stuffing box is available in two variations: Single Pack and Double Pack. Customers have the flexibility to choose between using 1045/4130 casting steel or ductile iron for the cap, glands, body, and base, depending on their specific requirements. The bottom of the stuffing box is equipped with API gauged threads, designed to match tubing EUE or LP connections. These stuffing boxes are suitable for a range of rod sizes, including 1 inch, 1.1/8 inches, 1.1/4 inches, 1.1/2 inches, and 1.3/4 inches. They are characterized by a simple structure, making installation and maintenance hassle-free. The option of single packing, double packing, or even triple packing ensures optimal sealing effectiveness, offering reliable performance and efficient sealing capabilities.

Features of stuffing box for polished rod:

Stuffing Box Detail information

|

||||||||||||||||||||||||||||||

| Product Tags: Oilfield Cementing Stuffing Box Triple Sealing Stuffing Box Single Stuffing Box Seal |

|

Composite Material Spiral Type Casing Centralizer 13 5/8 |

|

Bow Spring Centralizer slip on bow spring casing centralizer for sale |

|

API 6A Manifold Manual Hard Seal Flange Wellhead Hydraulic Gate Valve for Oil and Gas Industry |

|

API 6A Oilfiedl Equipment Casing Head Spoon Flange Valve Gate |

|

API 6A Oilfiedl Equipment Wellhead Casing Head |

|

Forging Alloy Steel Christmas Tree Wellhead Flange Casing Head Forging Processing Type |