High Quality Sulfur bentonite pastillator

|

|

Zhangjiagang Raidsant Machinery Co., Ltd. is majored in developing and manufacturing innovative powder cooling pelletizing machinery. With nearly 20 years' production history, we have a good market

in more than 20 provinces in China, and some of our products were

exported to Spain, America, Russia and Korea, etc. Our products: DZ

rotary type cooling pelletizer, rotary type steel belt cooling

slicer, double-belt cooling unit, etc. have got many national

patent certificates. Application:

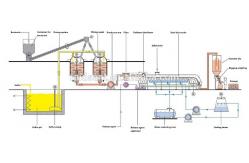

Working principle:

|

| Product Tags: industrial process equipment granules manufacturing machine |

|

Sodium Sulfide Wax Granulator Machine Rubber Auxiliary Steel Belt Pelletizer |

|

Stainless Steel Wax Granulator , Wax Prilling Machine Rubber Auxiliary Granulator |

|

Rotoform Wax Granulator Machine Steel Belt Chemical Material Trimellitic Anhydride |

|

Crumb Rubber Modified Bitumen Steel Belt Pastillator , Wax Making Machine Durable |

|

Water Cooling Flaking Wax Granulator Machine Customized Voltage Industrial |

|

Asphalt Chemical Making Machine , Steel Band Cooling Pelletizing Rotoform Machine |