Customized Polyamide Strip High Performance With Heat

Resistance/High Temperature Resistance

Product Introduction

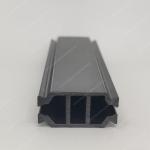

High Precision For Aluminum Sash Window Frame PA66 25% Fiberglass

Thermal Insulation barrier strips.

Inserted in the thermal break aluminium profiles, and being the

part of energy-saving window system for reducing heat conduction.

The shape I polyamide thermal barrier material can prevent the

window frame from dust and water and could realize a better Uf

value by sealing with a rubber profile, mostly used on the sash.

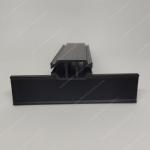

Broken Bridge aluminum thermal break strip is an important

criterion for distinguishing aluminum alloy doors and windows and

broken bridge aluminum doors and windows.It is precisely because of

the appearance of broken aluminum thermal break strips that the

aluminum doors and windows of the broken bridge have good thermal

insulation and sound insulation performance. The extruding high

precision polyamide thermal break strip is used in windows and

doors.Inserted in the thermal break aluminum profiles,it is the

part of energy-saving window system for reducing heat sonduction.

Advantages of using polyamide strips:

They provide a better thermal insulation.

They need lesser use of metals.

The polyamide strips are cost-effective.

They are easy to create thermal barriers with.

They help in resources to be conservedand can reduce operating

costs.

They ensure maximum stability of the structure.

They are more than effective in resisting condensation.

They don't require any special handling or fabrication.

Polywell Performance of PA66 GF25 Thermal Break Profiles

| NO. | Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

| | Material Properties |

| 1 | Density | g/cm3 | 1.3±0.05 | 1.28-1.35 |

| 2 | Linear expansion coefficient | K-1 | (2.3-3.5)×10-5 | (2.3-3.5)×10-5 |

| 3 | Vicat softening temperature | ºC | ≥230ºC | ≥233ºC |

| 4 | Melting point(0.45MPa) | ºC | ≥240 | ≥240 |

| 5 | Testing for tensile cracks | - | No cracks | No cracks |

| 6 | Shore hardness | - | 80±5 | 80-85 |

| 7 | Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥38 |

| 8 | Tensile strength(longitudinal) | MPa | ≥80a | ≥82a |

| 9 | Elasticity modulus | MPa | ≥4500 | ≥4550 |

| 10 | Elongation at break | % | ≥2.5 | ≥2.6 |

| 11 | Tensile strength(transverse) | MPa | ≥70a | ≥70a |

| 12 | High temperature tensile strength(transverse) | MPa | ≥45a | ≥47a |

| 13 | Low temperature tensile strength(transverse) | MPa | ≥80a | ≥81a |

| 14 | Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

| 15 | Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1.Sample water content less than 0.2% by weight.

2.Norm laboratory condition:(23±2)ºC and (50±10)% relative

humidity.

3.The specifications marked with "a" only applies to I-shape strip

otherwise, the specifications concluded between supplier and buyer

through consultation, shall be written in contract or purchase

order.

Storage Conditions

The strips will be stored in the ventilated and dry environment,

horizontally placed, paying attention to waterproof, keeping away

from the heat source, avoiding heavy pressure and the contact with

acid, alkali as well as organic solvent.

Delivery

We have the production capacity of 100000 meters per day. For

common specifications, we have molds, and will be shipped in 10-20

working days after receiving the deposit.

Packages

For all specifications/shapes, they could be packaged in linear,

the length will be 6 meters, or customized.

For the Shape "I", "C", and some simple shapes, they can be packed

in rolls. 400-600 meters/roll.

Our service

1. Expertise in the production of standard polyamide thermal break

strips.

2. Respect customers' needs, provide customized products, try best

to satisfy customers' requirements.

3. Fast service and on-time delivery

4. Strict quality control system, each production process will be

strictly supervised by us.

5.We can provide all products on the insulation strip production

line and the technical support.

Our Company

Our Company is located in the city of Zhangjiagang, Jiangsu

Province, China. We have been making research and development for

special material of PA66 thermal insulation strip since 2006.We

have a deep understanding and rich experience of the relevant

industry during this year.

We expanded our business scope since the year of 2010. We not only

produce PA66 granules and PA66 thermal barrier strips, but also

sell parallel twin-screw granulator, extruding machine, mould and

production technology.

we are developing overseas market. We are going to promote our

products all around the world, to seek win-win cooperation, mutual

benefits and mutual development with our customers.