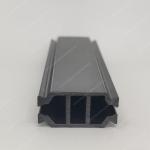

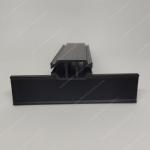

Plastic Extrusion Thermal Break Profile C Shape 14.8mm For Aluminum Windows

|

Product Description |

Name | Specification | Brand | Material |

Polyamide Granules | PA66 GF25 | Polywell | PA66, Fiberglass |

Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

Density | g/cm3 | 1.3±0.05 | 1.25-1.35 |

Linear expansion coefficient | K-1 | (2.3-3.5)×10-5 | (2.3-3.5)×10-5 |

Vicat softening temperature | ºC | ≥230ºC | ≥230ºC |

Melting point | ºC | ≥240 | ≥240 |

Testing for tensile cracks | - | No cracks | No cracks |

Shore hardness | - | 80±5 | 76-85 |

Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥35 |

Tensile strength(longitudinal) | MPa | ≥80a | ≥80a |

Elasticity modulus | MPa | ≥4500 | ≥4500 |

Elongation at break | % | ≥2.5 | ≥2.5 |

Tensile strength(transverse) | MPa | ≥70a | ≥70a |

High temperature tensile strength(transverse) | MPa | ≥45a | ≥45a |

Low temperature tensile strength(transverse) | MPa | ≥80a | ≥80a |

Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative

humidity.

3.The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

Storage Conditions

The strips will be stored in the ventilated and dry environment, horizontally placed, paying attention to waterproof, keeping away from the heat source, avoiding heavy pressure and the contact with acid, alkali as well as organic solvent.

Packages

For all specifications/shapes, they could be packaged in linear,

the length will be 6 meters, or customized.

For the Shape "I", "C", and some simple shapes, they can be packed

in rolls. 400-600 meters/roll.

Delivery

We have the production capacity of 100000 meters per day. For common specifications, we have molds, and will be shipped in 10-15 working days after receiving the deposit.

Our Service&Company

Before sales

1. introduce products in detail

2. recommend suitable solutions

3. provide with reference information

During manufacturing

1. provide with layout and engineering conditions

2. inform the processing status

3. offer related documents

After Sales

1. provide installation, commissioning and training

2. offer spare parts

3. Provide with necessary technical support

Welcome to visit our company!

Please feel free to contact us if you have any questions.

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |