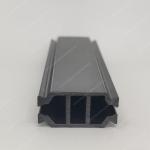

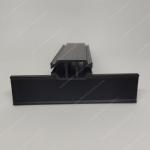

CT Shape Polyamide Thermal Insulating Strip Nylon Thermal Break Profile

|

|

Production Description

Shape CT extrusion thermal barrier strip for aluminium window

profiles. Inserted in the thermal break aluminium profiles, and

being the part of energy-saving window system for reducing heat

conduction. The shape CT polyamide thermal barrier material can

prevent the window frame from dust and water, also has a more

beautiful appearance than the shape I, could realize a better

Uf value by sealing with a rubber profile, mostly used on the

sash.

Advantages

Polywell PA66 GF25 thermal barrier strips Performance Table

1.Sample water content less than 0.2% by weight.

Storage Conditions

Packages

Our Service

Our Company

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thermal break aluminium profiles thermal break insulator | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |