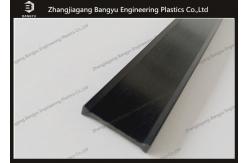

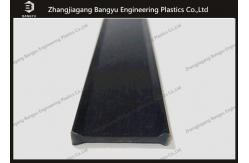

C Shape 14.8mm Plastic Extrusion Polyamide 66 Thermal Barrier Material in Aluminum

|

|

Product Description Over the years, polyamide heat-insulation strip has been widely

used in glass curtain walls due to its good properties and low

cost. Especially Polyamide 66 reinforced by 25% glass fiber

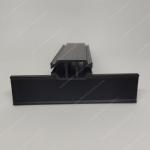

thermal break strips, they are inserted into aluminum window, door

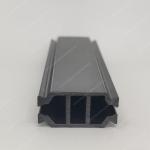

and facade profile for thermal insulation. The shape C polyamide thermal insulation strip can prevent the

window frame from dust and water, also has a more beautiful

appearance than the shape I, but not so firm. Advantages 1.Effectively increased thermal in the system property insulation. Product Parameters 1. Sample water content less than 0.2% by weight. 3.The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order. Packing & Delivery Packaging details:For all specifications/shapes, they could be packaged in linear,

the length will be 6 meters, or customized.For the Shape "I", "C",

and some simple shapes, they can be packed in rolls. 400-600

meters/roll. Our Service&Company Welcome to visit our company!Please feel free to contact us if you have any questions. Skype: live:lana_lou_5 Before sales1. introduce products in detail During manufacturing1. provide with layout and engineering conditions After Sales1. provide installation, commissioning and training |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thermal break aluminium profiles plastic extrusion profiles |

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |